In the current supply chain landscape, businesses should always be apt in delivering products and services based on customer demands despite inevitable disruptions. The clamor for sustainability adds to its complexity.

The only way to be efficient in supply chain and manufacturing is to apply advanced technological solutions such as AI, cloud-based tech, and IoT (Internet of Things). Implement these with Aratum’s suite of solutions to become resilient, sustainable, efficient and profitable.

Integration

Collaboration

Visibillitas

Demand Forecasting

Inventory Management

Quality Management

Sustainability

Risk Management

SCM involves seamlessly integrating various processes, including procurement, production, inventory management, logistics, and distribution, to optimize efficiency and reduce costs.

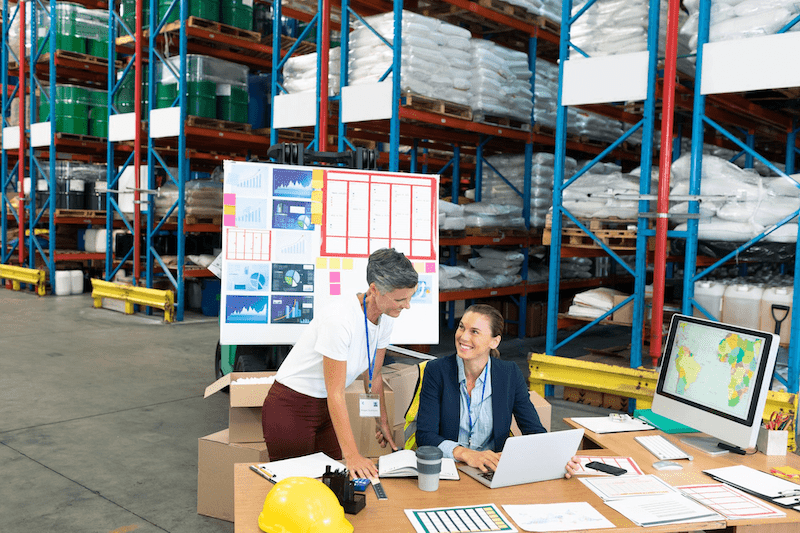

Effective SCM requires collaboration and coordination among suppliers, manufacturers, distributors, and retailers to ensure smooth operations and timely delivery of products to customers.

SCM relies on real-time visibility into the entire supply chain network, enabling stakeholders to track inventory levels, monitor production progress, and respond quickly to changes in demand or supply.

Accurate demand forecasting is crucial in SCM to anticipate customer demand, optimize inventory levels, and minimize stockouts or excess inventory.

SCM involves optimizing inventory levels to balance the costs of holding inventory against the risks of stockouts. Techniques such as Just-in-Time (JIT) inventory management and Vendor-Managed Inventory (VMI) are commonly used.

Quality control and assurance processes are integral to SCM to ensure that products meet quality standards throughout the manufacturing and distribution, reducing defects and rework.

Increasingly, sustainability considerations such as environmental impact, ethical sourcing, and social responsibility are becoming essential for SCM, driving companies to adopt sustainable practices across their supply chains.

SCM involves identifying and mitigating risks such as supply chain disruptions, geopolitical instability, natural disasters, or economic fluctuations that could impact the flow of goods and services.

SCM ensures the efficient management of medical supplies, equipment, and pharmaceuticals, optimizing inventory levels to meet patient needs while minimizing waste and reducing costs.

In retail, SCM focuses on inventory management, demand forecasting, and efficient logistics to ensure products are available at the right time and place, minimizing stockout and maximizing customer satisfaction.

SCM in pharmaceuticals involves strict regulation compliance, cold chain management for temperature-sensitive products, and efficient distribution to ensure the timely availability of medications to patients while maintaining product integrity.

SCM in e-commerce includes order processing, inventory management, and last-mile delivery optimization to fulfill customer orders quickly and accurately, enhancing the overall shopping experience.

SCM in transportation and logistics optimizes the movement of goods, selecting the most efficient transportation modes and routes, managing warehousing facilities, and tracking shipments to ensure on-time delivery while minimizing costs.

SCM in the cold chain industry involves maintaining temperature-controlled environments throughout the supply chain to preserve the quality and safety of perishable goods, such as food, pharmaceuticals, and vaccines.

SCM in finance involves managing cash flow, securities, and other financial products, optimizing processes to ensure liquidity, reducing transaction costs, and mitigating risks associated with market fluctuations.

In government, SCM encompasses procurement processes, inventory management of government assets, and disaster response logistics, ensuring efficient resource allocation and delivery of essential services to citizens.

SCM in manufacturing streamlines production processes, manages raw material procurement, and coordinates with suppliers to ensure uninterrupted production, reduce lead times, and improve overall efficiency.

SCM in cybersecurity involves managing the flow of digital assets, securing supply chain networks, and implementing measures to protect against cyber threats, ensuring the integrity and confidentiality of sensitive information.

SCM in dangerous goods warehouses involves strict compliance with safety regulations, specialized handling procedures, and effective risk management to ensure the safe storage and transportation of hazardous materials.

SCM in water and energy industries focuses on optimizing resource utilization, managing supply chains for equipment and materials, and implementing sustainable practices to minimize environmental impact and enhance efficiency.

Cost reduction in freight and overall operations

A Taiwanese manufacturer of computer and mobile accessories renowned for its high-quality products faced numerous challenges in its supply chain operations. It struggled with rising freight prices, fluctuating demand, port congestion, material shortages, lack of traceability, and limited operational visibility. These issues hindered the company’s ability to meet customer demands efficiently and impacted its bottom line.

With Aratum’s help, the company implemented an AI-powered, cloud-based supply chain management cloud software to improve its operations.

The bank turned to our solutions to streamline its operations in light of these challenges.

SCM manages the flow of goods and services, coordinating procurement, production, inventory management, logistics, and distribution to ensure efficient operations and customer satisfaction.

SCM is crucial for businesses to optimize efficiency, reduce costs, and enhance customer service. It helps organizations streamline processes, minimize inventory levels, improve collaboration with suppliers, and adapt to changes in demand or supply.

The key components of SCM include procurement, production planning, inventory management, logistics, distribution, and customer service. Effective coordination of these components is essential for a smooth flow of goods and services.

SCM benefits businesses by reducing operating costs, improving inventory turnover, enhancing customer satisfaction, minimizing lead times, mitigating supply chain risks, and fostering innovation through collaboration with suppliers and partners.

Common challenges in SCM include demand variability, supply chain disruptions, inventory management complexities, globalization issues, regulatory compliance, sustainability concerns, and technology integration.

Technology plays a significant role in SCM by enabling real-time visibility into supply chain processes, optimizing inventory levels, automating order processing and shipment tracking tasks, enhancing communication with suppliers, and facilitating data-driven decision-making.

SCM encompasses a broader scope than logistics. While logistics focuses on the physical movement and storage of goods, SCM includes additional activities such as procurement, production planning, inventory management, and distribution.

Companies can improve SCM practices by adopting lean principles, implementing advanced planning and scheduling systems, collaborating with suppliers and partners, investing in supply chain visibility tools, and continuously monitoring and optimizing processes. Using a cloud supply chain management software can help these processes.

Sustainability is becoming increasingly crucial in SCM, with businesses focusing on reducing carbon emissions, minimizing waste, promoting ethical sourcing practices, and implementing environmentally friendly packaging and transportation solutions.

Key trends shaping the future of SCM include adopting artificial intelligence and machine learning for predictive analytics, the rise of blockchain technology for supply chain transparency, the expansion of e-commerce and omnichannel distribution strategies, and the growing emphasis on circular economy principles for resource efficiency and waste reduction.

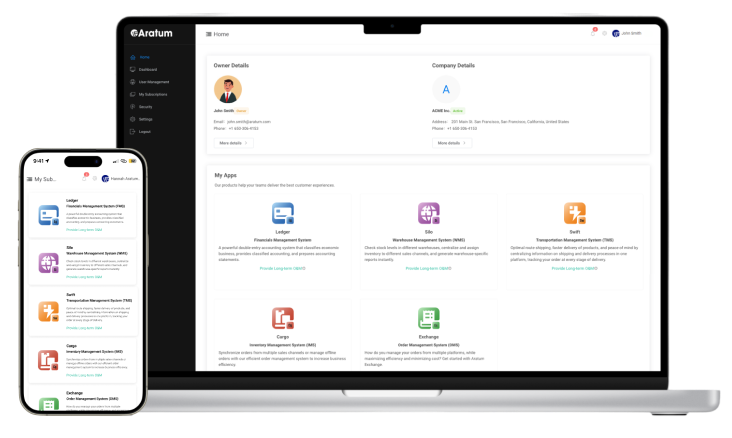

To implement efficient supply chain & manufacturing in your business, you can rely on Aratum’s AI and cloud-based solutions to help you get started and gain business visibility, efficiency, and resiliency.

Aratum is a globally recognized software provider specializing in developing supply chain management software. Our software solutions incorporate advanced algorithms and optimized data structures to facilitate efficient data processing and information dissemination across organizations.

Leveraging cutting-edge technologies such as machine learning and artificial intelligence, the software enables automated decision-making and real-time analytics, enhancing supply chain visibility and improving overall performance.

With a focus on delivering robust and scalable solutions, Aratum is committed to providing our clients with the tools necessary to optimize their supply chain operations and gain a competitive edge in your respective markets.

© 2024 Aratum or an Aratum affiliate company. All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of Aratum or an Aratum affiliate company. The information contained herein may be changed without prior notice. Some software products marketed by Aratum and its distributors contain proprietary software components of other software vendors. National product specifications may vary. These materials are provided by Aratum or an Aratum affiliate company for informational purposes only, without representation or warranty of any kind, and Aratum or its affiliated companies shall not be liable for errors or omissions with respect to the materials. The only warranties for Aratum or Aratum affiliate company products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. In particular, Aratum or its affiliated companies have no obligation to pursue any course of business outlined in this document or any related presentation, or to develop or release any functionality mentioned therein. This document, or any related presentation, and Aratum’s or its affiliated companies’ strategy and possible future developments, products, and/or platforms, directions, and functionality are all subject to change and may be changed by Aratum or its affiliated companies at any time for any reason without notice. The information in this document is not a commitment, promise, or legal obligation to deliver any material, code, or functionality. All forward-looking statements are subject to various risks and uncertainties that could cause actual results to differ materially from expectations. Readers are cautioned not to place undue reliance on these forward-looking statements, and they should not be relied upon in making purchasing decisions. Aratum and other Aratum products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Aratum (or an Aratum affiliate company) globally. All other product and service names mentioned are the trademarks of their respective companies. See aratum.com for additional trademark information and notices.