A warehouse is a house that protects a supply chain business. Like a family home, it should be sustained to keep the overall business processes afloat.

As your business grows, challenges may arise, affecting your inventory, deliveries, finances, and other warehouse operations. Hence, an AI and cloud-based warehouse management system can help address your company’s growing pains.

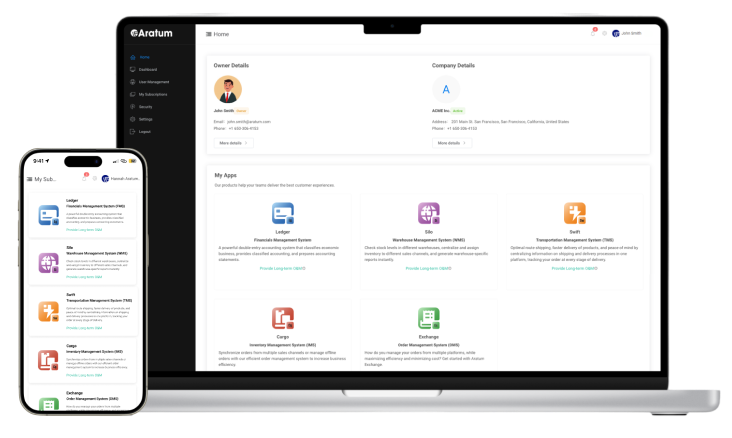

With Aratum WMS Solutions, you can reach new heights, be at the top of your industry, and achieve maximum profitability.

Receiving and Putaway

Picking and Packing

Inventory Management

Order Management

Warehouse Layout Optimization

Labor Management

Cross-Docking and Transfers

Real-time Visibility and Reporting

Integration with Other Systems

Scalability and Flexibility

Warehouse management systems streamline the receiving process by automating tasks such as receiving goods, checking for damages, and updating inventory records. It also directs the putaway of received items to the appropriate storage locations based on predefined rules or optimization algorithms.

Warehouse management systems employ various picking strategies (e.g., wave picking, zone picking, batch picking) to optimize the picking process based on factors like order volume, item characteristics, and warehouse layout. It guides warehouse staff through the picking and packing processes, ensuring efficient resource utilization.

Warehouse management systems help in tracking inventory levels, locations, and movements within the warehouse. It provides real-time visibility into stock levels, enabling better inventory control and reducing the risk of stockouts or overstocking.

Warehouse management systems facilitate order processing by efficiently managing order picking, packing, and shipping processes. They also optimize order fulfillment workflows to minimize errors and improve order accuracy.

Warehouse management systems help design and optimize warehouse layouts to maximize space utilization and streamline material flow. It considers factors such as SKU velocity, storage requirements, and picking patterns to design efficient storage configurations.

Warehouse management systems provide tools for workforce planning, performance tracking, and labor productivity monitoring. It helps manage labor resources effectively by assigning tasks, tracking labor hours, and measuring individual or team performance against predefined KPIs.

Warehouse management systems facilitate cross-docking operations by directly transferring goods from inbound to outbound shipments without storing them in the warehouse. It also supports inter-warehouse transfers by managing the movement of goods between different warehouse locations.

Warehouse management systems offer real-time visibility into warehouse operations through dashboards, reports, and analytics tools. It provides insights into key performance metrics such as order cycle time, inventory turnover, and warehouse capacity utilization, enabling data-driven decision-making.

Warehouse management systems integrate seamlessly with other supply chain management systems such as ERP (Enterprise Resource Planning), TMS (Transportation Management System), and CRM (Customer Relationship Management) to ensure end-to-end visibility and coordination across the supply chain.

A good Warehouse management system is scalable to accommodate growing business needs and flexible enough to adapt to changing warehouse processes and workflows. It should support customization and configuration options to meet specific business requirements.

A WMS software is critical in ensuring the timely and accurate distribution of medical supplies and equipment, optimizing inventory levels, and maintaining regulatory compliance to support efficient healthcare operations.

A WMS software streamlines inventory control, order processing, and distribution logistics, enhancing store replenishment, optimizing stock levels, and ensuring seamless product availability across brick-and-mortar locations and online channels to meet diverse customer demands and drive sales growth.

A WMS software ensures the proper handling and tracking of temperature-sensitive medications, regulatory compliance, and efficient distribution to support patient care and safety.

A WMS software orchestrates the efficient storage, retrieval, and dispatch of products, optimizing inventory accuracy, order fulfillment speed, and overall operational efficiency to meet the demands of online shoppers and maintain a competitive advantage in the digital marketplace.

A WMS software streamlines the flow of goods, optimizes storage space utilization, and enhances order fulfillment processes, improving efficiency and customer satisfaction.

A WMS software monitors and controls temperature-sensitive storage environments, ensuring the integrity of perishable goods throughout the supply chain, from production to delivery.

A WMS software facilitates the secure storage and tracking of sensitive documents and assets, ensuring compliance with regulatory requirements and optimizing operational workflows.

A WMS software supports efficient procurement, inventory management, and asset tracking across various departments and agencies, optimizing resource allocation and transparency.

A WMS software optimizes material flow, inventory accuracy, and production processes, ensuring the timely availability of raw materials and finished goods to meet production schedules and customer demands.

A WMS software secures sensitive data and assets through robust access controls, encryption, and threat detection measures, safeguarding against cyber threats and ensuring data integrity within digital warehouses.

A WMS software enforces strict safety protocols, regulatory compliance, and specialized handling procedures to mitigate storage and transportation risks of hazardous materials.

A WMS software facilitates the storage, distribution, and tracking of critical infrastructure components and supplies, ensuring reliable access to essential resources and supporting sustainable resource management practices.

A growing herbal supplement company in the USA faced inefficiencies in its warehouse operations due to the unforeseen demand for its products. The company relied on manual inventory, leading to several stockouts, delayed order fulfillment, and compliance issues.

Faced with these problems, they turned to our solutions to improve their warehouse operations.

Warehouse management systems involve the planning, organizing, and controlling of warehouse operations to ensure the efficient storage, handling, and movement of goods within a supply chain.

A warehouse management system is crucial for optimizing inventory control, order fulfillment, and overall supply chain efficiency. This can lead to cost savings, improved customer satisfaction, and competitive advantage.

A WMS improves efficiency by automating manual tasks, optimizing storage space utilization, reducing picking errors, streamlining workflows, and providing real-time visibility into warehouse operations.

Common picking strategies include single-order picking, batch picking, zone picking, wave picking, and pick-to-carton.

Warehouse management systems employ barcode scanning, RFID technology, and real-time inventory tracking to ensure accurate inventory counts, minimize stock discrepancies, and prevent stockouts or overstocking.

WMS solutions help pharmaceutical, food, and other industries comply with regulatory requirements by enforcing temperature controls, lot tracking, expiration date management, and documentation management.

Labor management features in WMS software optimize workforce productivity by assigning tasks, tracking labor performance, managing shifts, and providing training and performance feedback to warehouse staff.

WMS integrates with ERP, TMS, CRM, and other systems to facilitate seamless data exchange, coordination, and visibility across the supply chain network.

Common challenges include inventory inaccuracies, order picking errors, inefficient layout design, poor workforce productivity, inadequate technology integration, and compliance issues.

Companies can optimize warehouse layout and design by considering SKU velocity, storage requirements, picking patterns, material flow, automation, and robotics.

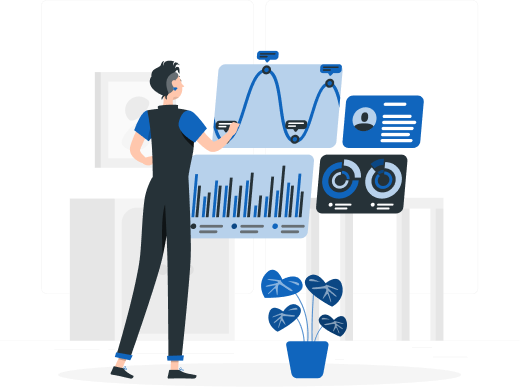

To implement enterprise performance management software, you can rely on Aratum solutions tailored to your business requirements. These solutions can help you get started and gain visibility, efficiency, and resiliency.

Aratum is a globally recognized software provider specializing in developing supply chain management solutions. Our software solutions incorporate advanced algorithms and optimized data structures to facilitate efficient data processing and information dissemination across organizations.

Leveraging cutting-edge technologies such as machine learning and artificial intelligence, the software enables automated decision-making and real-time analytics, enhancing supply chain visibility and improving overall performance.

With a focus on delivering robust and scalable solutions, Aratum is committed to providing our clients with the tools necessary to optimize their supply chain operations and gain a competitive edge in your respective markets.

© 2024 Aratum or an Aratum affiliate company. All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of Aratum or an Aratum affiliate company. The information contained herein may be changed without prior notice. Some software products marketed by Aratum and its distributors contain proprietary software components of other software vendors. National product specifications may vary. These materials are provided by Aratum or an Aratum affiliate company for informational purposes only, without representation or warranty of any kind, and Aratum or its affiliated companies shall not be liable for errors or omissions with respect to the materials. The only warranties for Aratum or Aratum affiliate company products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. In particular, Aratum or its affiliated companies have no obligation to pursue any course of business outlined in this document or any related presentation, or to develop or release any functionality mentioned therein. This document, or any related presentation, and Aratum’s or its affiliated companies’ strategy and possible future developments, products, and/or platforms, directions, and functionality are all subject to change and may be changed by Aratum or its affiliated companies at any time for any reason without notice. The information in this document is not a commitment, promise, or legal obligation to deliver any material, code, or functionality. All forward-looking statements are subject to various risks and uncertainties that could cause actual results to differ materially from expectations. Readers are cautioned not to place undue reliance on these forward-looking statements, and they should not be relied upon in making purchasing decisions. Aratum and other Aratum products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Aratum (or an Aratum affiliate company) globally. All other product and service names mentioned are the trademarks of their respective companies. See aratum.com for additional trademark information and notices.