Supply chain planning is a fundamental step in running supply chain-based businesses. However, proper planning involves implementing cutting-edge and robust technological solutions for seamless industrial operations and processes.

With Aratum Solutions, your company can swiftly adapt to dynamic market conditions, improve sales and operations planning (s&op), and maintain a competitive edge in the industry.

Grow your business to new heights and be at the top of the game with Aratum’s robust and scalable AI technology and machine learning infrastructure.

Demand Forecasting and Predictive Analytics

Scenario-Based Planning

Real-Time Performance Monitoring

Demand-Supply Balancing

Automated Decision-Making

Transportation Optimization

Dynamic Inventory Optimization

Predictive Maintenance

Supplier Relationship Management

Continuous Improvement and Learning

Demand forecasting and predictive analysis utilize historical data and market trends to anticipate future demand for products or services. Organizations can effectively make informed decisions about inventory management, production planning, and customer service by analyzing patterns and external factors to meet anticipated demand.

Scenario analysis and simulation enable organizations to assess the potential impact of various scenarios on their supply chain, such as demand fluctuations, disruptions, or policy changes. By running simulations based on different parameters and assumptions, businesses can identify risks, opportunities, and optimal strategies to enhance resilience and agility within their supply chain operations.

Real-time performance monitoring enables organizations to track key metrics and indicators instantly, providing immediate insights into the health and efficiency of their operations. By leveraging real-time data and analytics, businesses can identify trends, detect issues early, and make timely adjustments to optimize performance and achieve strategic objectives.

Demand-supply balancing involves optimizing the match between customer demand and available supply across the supply chain. Organizations can meet customer needs by dynamically adjusting production, inventory levels, and distribution while minimizing excess inventory or stockouts. This process requires continuous monitoring of demand signals, inventory levels, and production capabilities to make agile decisions and maintain an optimal balance between supply and demand.

Automated decision-making involves leveraging algorithms and predefined rules to make routine decisions without human intervention. By automating tasks such as order processing, inventory replenishment, and scheduling, organizations can improve efficiency, reduce errors, and free up human resources to focus on higher-value activities. This approach relies on data-driven insights and real-time analytics to ensure decisions align with business objectives and optimize outcomes.

Transportation optimization involves leveraging algorithms and data analytics to streamline the movement of goods across the supply chain. By optimizing routes, modes of transportation, and shipment consolidation, organizations can reduce costs, improve delivery times, and minimize environmental impact. This process requires real-time visibility into transportation data, including vehicle tracking, traffic conditions, and carrier performance, to make informed decisions and continuously optimize transportation operations.

Dynamic inventory optimization employs algorithms and real-time data analysis to manage inventory levels efficiently. Organizations can minimize carrying costs while ensuring product availability by adjusting stock levels based on demand forecasts, lead times, and supply chain constraints. This approach requires agile decision-making and seamless integration with supply chain partners to adapt to changing market conditions and demand patterns, ultimately improving customer satisfaction and profitability.

Predictive maintenance utilizes machine learning algorithms and sensor data to anticipate equipment failures before they occur. Organizations can schedule maintenance proactively by analyzing equipment performance data and identifying patterns indicative of potential issues, reducing downtime and minimizing costly repairs. This approach requires real-time equipment health monitoring and predictive analytics capabilities to forecast maintenance needs accurately, ultimately improving asset reliability and operational efficiency.

Supplier Relationship Management (SRM) involves strategically managing interactions with suppliers to maximize the value derived from these relationships. By leveraging data analytics and collaboration tools, organizations can assess supplier performance, mitigate risks, and identify opportunities for improvement. This process requires transparent communication, mutual trust, and shared goals to foster long-term partnerships that drive innovation, reduce costs, and enhance supply chain resilience.

Continuous improvement and learning involve systematically refining processes and strategies based on data-driven insights and feedback. By leveraging analytics and performance metrics, organizations can identify areas for optimization, implement changes, and evaluate outcomes to drive ongoing efficiency, quality, and innovation improvements. This iterative approach fosters a culture of innovation and adaptability, enabling organizations to stay competitive and responsive to evolving market dynamics.

Supply Chain Planning ensures the timely availability of medical supplies and equipment, optimizes inventory management, and streamlines logistics for efficient patient care.

Supply Chain Planning predicts demand, manages inventory levels, and optimizes logistics operations to ensure product availability and customer satisfaction.

Supply Chain Planning manages production schedules, optimizes medication inventory levels, and ensures compliance with regulatory standards for safe and efficient distribution.

Supply Chain Planning streamlines order fulfillment processes, optimizes inventory management, and coordinates logistics operations to ensure timely customer delivery.

Supply Chain Planning optimizes routes and modes of transportation and load consolidation to minimize costs and improve efficiency in moving goods from suppliers to customers.

Supply Chain Planning maintains temperature-controlled storage and transportation for perishable goods, ensuring product quality and safety throughout the supply chain.

Supply Chain Planning coordinates investment management, cash flow forecasting, and risk mitigation strategies to optimize financial operations and meet customer needs.

Supply Chain Planning efficiently manages resources and services, coordinates procurement and distribution, and ensures transparency and accountability in government operations and service delivery.

Supply Chain Planning Involves Planning production schedules, optimizing inventory levels, and coordinating logistics operations to ensure efficient production and delivery of goods to customers.

Supply Chain Planning secures digital assets and systems critical to operations, assesses risks, and implements incident response plans to protect against cyber threats.

Supply Chain Planning ensures safe handling and storage of hazardous materials, compliance with regulatory standards, and implementation of emergency response protocols.

Supply Chain Planning coordinates procurement and distribution of resources, optimizes inventory management, and ensures efficient delivery to meet demand while minimizing waste.

A hazmat warehouse in California, which stores and handles chemicals, struggled with manual inventory management. They often needed to be more accurate in tracking inventory levels, leading to overstocking certain hazardous materials and increased compliance risks.

With Aratum’s help, the warehouse implemented a cloud-based and AI-powered supply chain planning system to address its challenges.

SCP involves strategically managing resources, processes, and activities in sourcing, producing, and delivering goods or services to customers. It encompasses various functions such as demand forecasting, inventory management, production planning, and logistics optimization.

Effective supply chain planning is crucial for optimizing operations, reducing costs, and improving customer satisfaction. It helps organizations anticipate demand, manage inventory efficiently, minimize risks, and respond effectively to changes in market conditions.

Key components of SCP include demand planning, inventory planning, production planning, distribution planning, and transportation planning. These components work together to ensure the supply chain’s seamless flow of goods or services.

While SCP focuses on strategic planning and optimizing supply chain activities, SCM encompasses the broader scope of coordinating and managing the entire supply chain ecosystem, including sourcing, manufacturing, distribution, and logistics.

Common challenges in SCP include demand volatility, inventory optimization, supplier management, transportation constraints, regulatory compliance, and supply chain disruptions such as natural disasters or geopolitical events.

Technology, such as advanced analytics, AI, machine learning, and cloud-based platforms, enhances SCP. These technologies enable organizations to leverage data-driven insights, automate processes, improve decision-making, and enhance collaboration across the supply chain.

Organizations can improve SCP by investing in advanced planning tools and technologies, enhancing data visibility and accuracy, fostering collaboration with supply chain partners, implementing robust risk management strategies, and continuously monitoring and adapting to changing market conditions.

AI and cloud-based tech offer several benefits, including improved forecast accuracy, reduced inventory carrying costs, optimized production scheduling, enhanced customer service levels, and better alignment of supply chain activities with business objectives.

Organizations can measure the effectiveness of SCP through key performance indicators (KPIs) such as forecast accuracy, inventory turnover, on-time delivery performance, supply chain costs, and customer satisfaction levels.

Best practices for SCP include adopting a demand-driven approach, collaborating closely with suppliers and customers, investing in data analytics and scenario planning, implementing agile and responsive supply chain strategies, and continuously evaluating and optimizing supply chain processes for efficiency and resilience.

Supply chain planning and S&OP are related processes that balance supply and demand. Supply chain planning optimizes the flow of goods, while S&OP integrates sales forecasts and production plans for efficient resource allocation. Together, they ensure organizations meet customer demand while effectively managing operational capabilities.

To implement streamlined Supply Chain Planning, you can rely on Aratum’s AI and cloud-based solutions to help you get started and gain business visibility, efficiency, and resiliency.

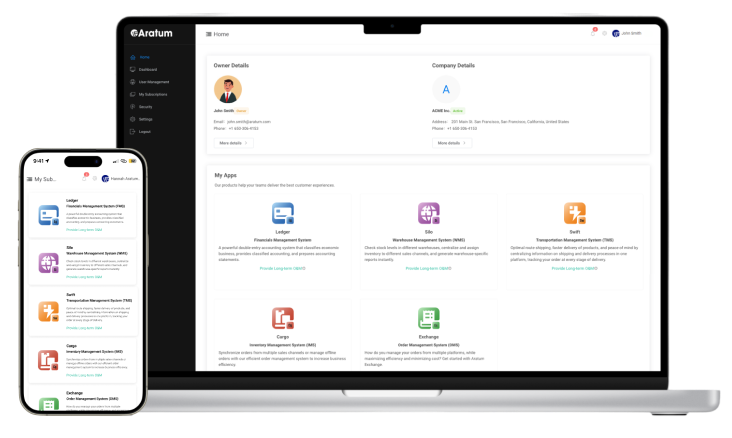

Aratum is a globally recognized software provider specializing in developing supply chain management solutions. Our software solutions incorporate advanced algorithms and optimized data structures to facilitate efficient data processing and information dissemination across organizations.

Leveraging cutting-edge technologies such as machine learning and artificial intelligence, the software enables automated decision-making and real-time analytics, enhancing supply chain visibility and improving overall performance.

With a focus on delivering robust and scalable solutions, Aratum is committed to providing our clients with the tools necessary to optimize their supply chain operations and gain a competitive edge in your respective markets.

© 2024 Aratum or an Aratum affiliate company. All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of Aratum or an Aratum affiliate company. The information contained herein may be changed without prior notice. Some software products marketed by Aratum and its distributors contain proprietary software components of other software vendors. National product specifications may vary. These materials are provided by Aratum or an Aratum affiliate company for informational purposes only, without representation or warranty of any kind, and Aratum or its affiliated companies shall not be liable for errors or omissions with respect to the materials. The only warranties for Aratum or Aratum affiliate company products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. In particular, Aratum or its affiliated companies have no obligation to pursue any course of business outlined in this document or any related presentation, or to develop or release any functionality mentioned therein. This document, or any related presentation, and Aratum’s or its affiliated companies’ strategy and possible future developments, products, and/or platforms, directions, and functionality are all subject to change and may be changed by Aratum or its affiliated companies at any time for any reason without notice. The information in this document is not a commitment, promise, or legal obligation to deliver any material, code, or functionality. All forward-looking statements are subject to various risks and uncertainties that could cause actual results to differ materially from expectations. Readers are cautioned not to place undue reliance on these forward-looking statements, and they should not be relied upon in making purchasing decisions. Aratum and other Aratum products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Aratum (or an Aratum affiliate company) globally. All other product and service names mentioned are the trademarks of their respective companies. See aratum.com for additional trademark information and notices.