Managing a complex global supply chain is increasingly challenging, especially when sourcing, producing, and shipping goods across multiple countries. Numerous touchpoints, shifting international regulations, and changing consumer demands make agility essential. Businesses must continuously evaluate and refine their supply chain strategies to ensure efficiency, cost-effectiveness, and resilience. This requires real-time monitoring, optimized logistics, and adaptation to disruptions like geopolitical events, trade tariffs, or natural disasters.

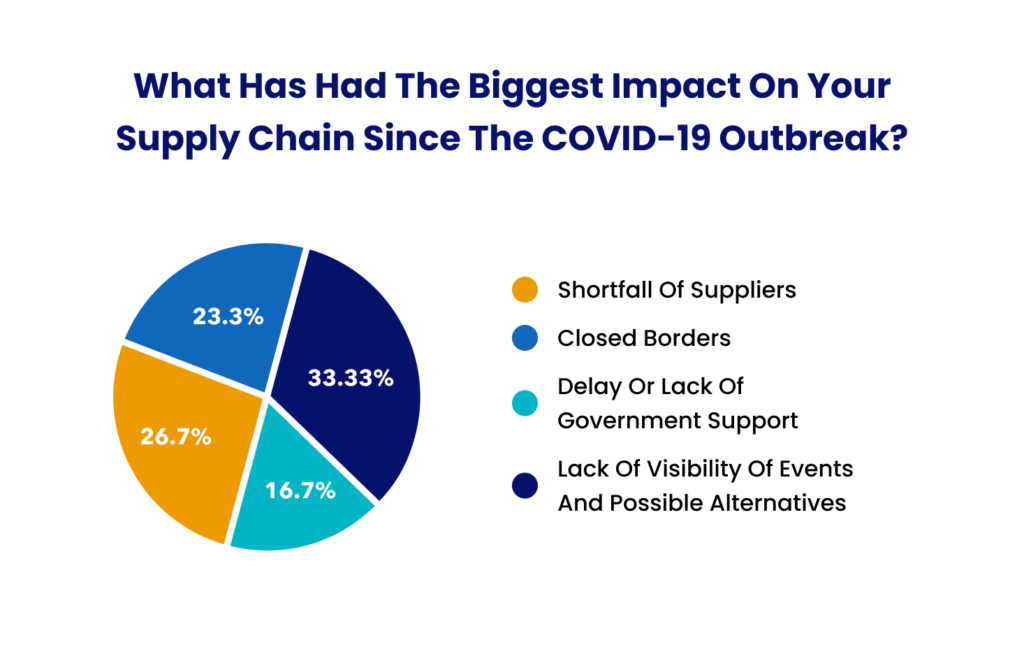

The COVID-19 pandemic caused major supply chain disruptions, leading to inventory shortages, decreased productivity, and demand spikes. However, customers’ expectations for on-time deliveries have remained unchanged despite the turmoil.

To adapt to the “new normal,” shippers have started looking for methods to remain one step ahead. Many companies have resorted to supply chain localization, moving their businesses closer to a company’s primary location and areas of strong demand. As a result, operations may become more streamlined and seamless.

This article will tackle:

- Opportunities that come with Supply Chain Localization

- Five Supply Chain Localization Strategies for Your Business

Supply chain localization involves producing and distributing products on a local level. Simply put, supply chain localization means purchasing where you sell and selling where you source. Even before the pandemic, supply chain localization was a growing trend as countries pushed for stronger domestic production, enhancing supply chain resilience.

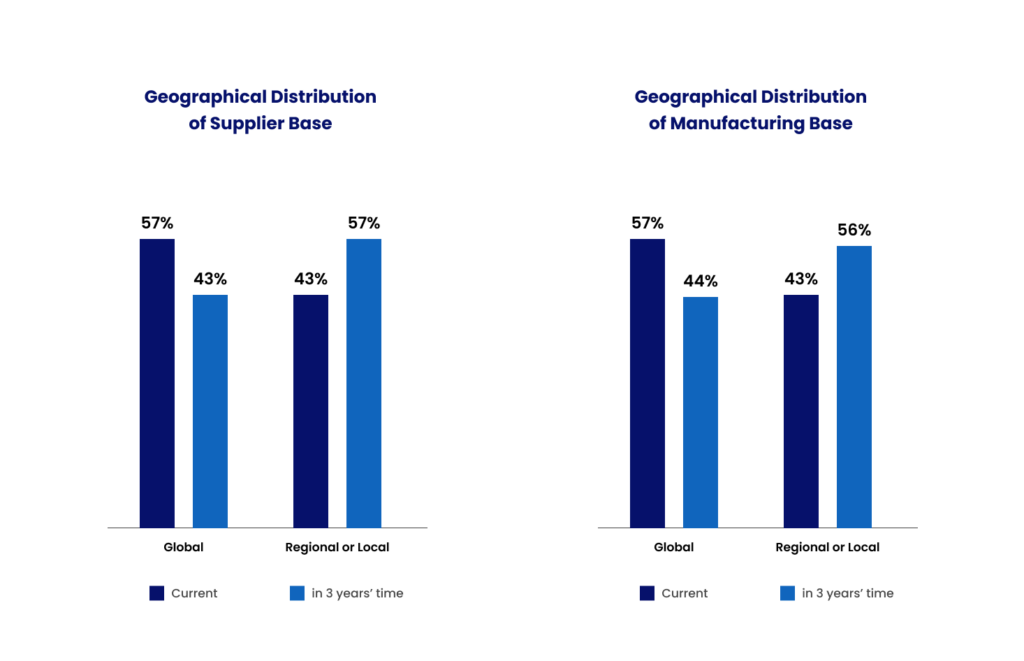

Deloitte reports that 62% of U.S. firms have already begun nearshoring or reshoring their manufacturing. Businesses in other countries are increasingly adopting similar strategies. In Europe, 60% of supply chain executives said they intend to bring back some of their manufacturing from Asia.

Localizing operations necessitates a comprehensive strategy that evaluates each facet and phase of the supply chain. You’ll need to consider procuring raw materials and distributing them to stores and customers. This strategy differs from the old “one-size-fits-all” approach when a business would unify its supply chain, marketing, shop layouts, and merchandise across all its locations.

Modern consumers are more likely to respond to distinct and customized shopping experiences. Supply chain localization allows companies to target particular client groups directly by customizing supply chains and logistics for various markets. It might entail completing orders from several locations to shorten delivery times or obtaining components locally rather than abroad.

Opportunities that come with a Localized Supply Chain

Companies must consider—and occasionally reconsider—the logistics of selling their goods abroad. Supply chain management, which influences customer experience, is crucial to success.

Clearly, a flawed supply chain can hurt a business’s profitability. It can prevent manufacturers from getting raw materials on time and cause consumers to receive their items late.

Supply chain localization helps avoid these issues by bringing operations closer to home, making them more resilient. Reshoring has become a practical and popular method to keep supply chains afloat. It involves moving operations and manufacturing back to your nation or origin from overseas. Reshoring is primarily used to secure valuable raw materials.

Nearshoring is also gaining popularity. It allows firms to move operations and manufacturing to a neighboring country where operational costs can be cheaper.

Increased Cost Savings

Reshoring can help you achieve considerable cost reductions. A supply chain that functions in a more accessible location can reduce hidden costs and increase overall visibility.

For instance, many companies import components and materials from all over the world. These resources must first be kept overseas and transported long distances to reach their destination. The movement of these goods requires the assistance of several logistics partners. A localized supply chain reduces transportation needs, making the process more efficient and cost-effective.

Greater Flexibility

Local suppliers are typically more responsive and communicative than distant ones. This makes it easier and faster to spot problems with the supply chain early on, respond to interruptions, and modify inventories in real-time.

For example, a localized supply chain facilitates faster product delivery and quicker manufacturing ramp-up in the event of a demand increase in a particular area.

Sustainable Operations

Supply chain localization shortens shipping distance, cutting emissions and energy use. A green production method and sustainability will be easier to achieve. Engaging in environmentally friendly business practices increases customer trust in your business.

Millennials and Gen Zs, in particular, are more likely to purchase goods with “clean labels.” These typically include information about the product’s origins and contents.

Encourages Supply Chain Innovation

Adhering to a one-size-fits-all supply chain strategy can result in rigidity. This approach stifles experimentation, leading to a need for more innovation.

Supply chain localization enables businesses to develop according to market and client preferences. Compare this to imposing supply chain procedures into a single strategy across all customer groups and locales. Reshoring encourages innovation and streamlines operations, encouraging a more open and creative work environment.

Five Localization Strategies for Your Supply Chain

Supply chain localization requires a substantial initial investment in manufacturing, warehousing, and material procurement. Modern and advanced technologies that provide visibility throughout the supply chain will facilitate this shift. Thorough planning and execution allow you to increase value, lower supply chain risks, and avoid disruptive and expensive issues.

1. Make Long-Term Goals

Supply chain localization is a long-term strategy for how your business sources supplies. It would be best to consider how your supply chain will change over time and not only focus on making decisions that will yield current value.

Rather than focusing solely on cost-cutting, design a supply chain environment that can adapt and improve along your changing strategic goals.

2. Leverage Supply Chain Technology

Technologies such as inventory management systems (IMS), order management systems (OMS), and warehouse management systems (WMS) software can reduce instability in disrupted supply chains. These systems provide warehouses and clients with real-time data on inventory levels, receipts, orders, shipments, and shipping information. They also help avoid overstocking and overselling of products.

Demand forecasting and business intelligence can be implemented to understand better where lead times and demand might fluctuate.

Proximity to suppliers won’t matter if you lack the technology to communicate effectively.

3. Work With the Right Partners

Even if you can’t get all your components and supplies locally, looking into some nearby alternatives is worthwhile—partnering with vendors who align with your business goals.

Because of their expertise in handling supplier, customer, and shipping carrier relationships, third-party logistics (3PL) warehouses are a prime candidate to lead supply chain localization initiatives. These third-party partners must be able to provide the services you require. If you are still looking for suppliers in your area, look for suppliers in your time zone. Doing so will allow you to collaborate and communicate easily while supporting other local companies.

Look into a service provider’s history of producing high-quality work on schedule and under budget. Choose partners with a proven track record to ensure your supply chain localization efforts succeed. Timely delivery and first-rate customer service are prerequisites for every successful supply chain localization plan.

4. Allocate Inventory for Specific Segments

Take advantage of client data obtained through an order management software. Do customers in particular regions purchase certain goods or services more frequently than others? Identify which of your products sell out quickly and which could be faster-moving. For a more customized and localized experience, directly target distinct client segments with your offers and marketing messaging. This insight helps you better target your supply chain localization efforts.

5. Make Use of Multiple Distribution Hubs

Rather than using one big central hub, you can establish several smaller distribution hubs to help you satisfy customer expectations. Strategically located hubs speed delivery, improve sustainability and reduce missed deadlines. To determine where creating a secondary distribution center would make sense, determine where most of your consumers are. Next, decide which items are most in demand in each area so your inventory can be stocked appropriately.

The COVID-19 pandemic has drastically changed the way we approach global business. Relying on international supply chains isn’t necessarily a bad thing. However, having more links in a chain can make it more vulnerable to interruptions.

Supply chain management must proactively maintain customer satisfaction in a rapidly changing market. It identifies opportunities for innovation and improvement based on customer demand, new trends, and external disturbances.

Supply chain localization goes beyond tailoring products to regional market needs; it encompasses production methods, site selection, and logistics. You need a supply chain that is adaptable enough to stay local from the point of origin to the point of sale if you want to have an international impact.

Aratum is vital to any supply chain localization plan. This management software syncs all of your supply chain data into one console. Make your business more resilient with real-time visibility and data intelligence. Book a demo to see how technology can transform the way you manage your supply chain.

The featured photo of this article was sourced from freepik.