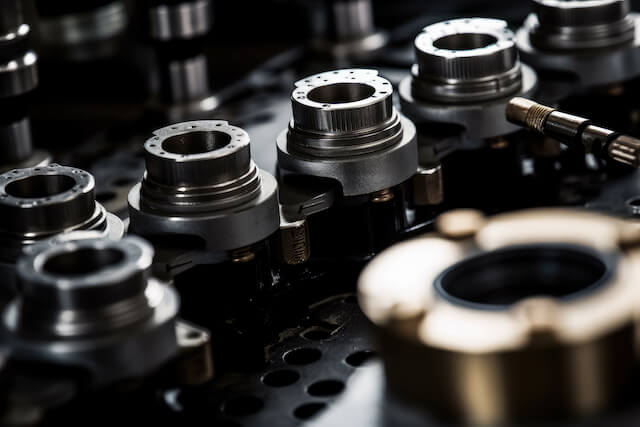

Efficient parts inventory management is one of the foundations of supply chain operational excellence. Companies often have problems with equipment downtime, stock discrepancies, and inventory inaccuracies.

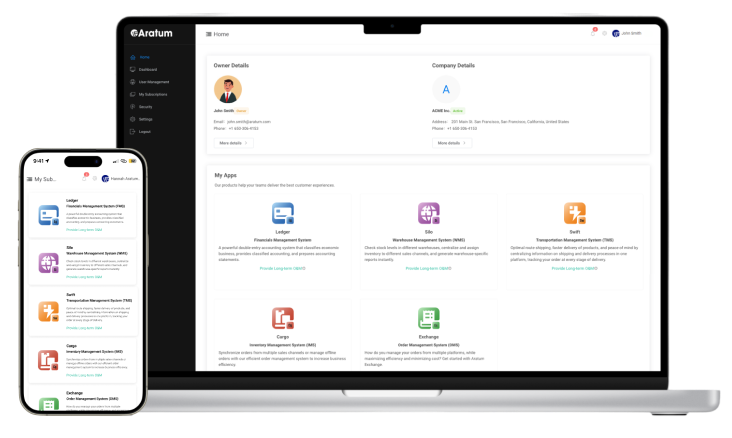

Aratum’s advanced product suite includes parts inventory management software, which equips business processes with real-time inventory tracking, automated reordering, and comprehensive analytics, shedding light on all their woes.

Real-Time Inventory Tracking

Automated Reordering

Barcode Scanning

Multi-Warehouse Management

Supplier Management

Reporting and Analytics

Integration Capabilities

User Access Controls

Customizable Alerts and Notifications

Mobile Accessibility

This feature allows users to monitor stock levels in real-time, ensuring accurate inventory counts at all times. By providing up-to-the-minute inventory data it helps prevent stockouts and overstocking.

The software can automatically generate purchase orders when stock levels fall below a predefined threshold. This ensures that essential parts are always in stock, reducing downtime and operational disruptions.

Integrated barcode scanning speeds up the process of inventory updates and order processing. It enhances accuracy by reducing manual entry errors and streamlines inventory audits.

Users can manage inventory across multiple warehouse locations from a single platform. This feature provides visibility into stock levels at all locations, facilitating better inventory distribution and fulfillment.

The software maintains a database of suppliers, including their contact details, pricing, and lead times. It helps manage supplier relationships and streamline the procurement process.

Generate detailed reports and analytics to gain insights into inventory performance, usage patterns, and demand forecasts. This data-driven approach supports better decision-making and strategic planning.

Seamlessly integrate with other business systems such as ERP, CRM, and accounting software. This ensures data consistency across platforms and improves overall operational efficiency.

Assign specific access permissions to users based on their roles within the organization. This enhances security by restricting sensitive inventory information to authorized personnel only.

Set up custom alerts for low stock levels, expiring products, and other critical inventory events. Timely notifications help in proactive inventory management and prevent potential issues.

Access inventory management features on the go through mobile apps. This provides flexibility and convenience for remote monitoring and inventory management.

Parts inventory management software helps automotive manufacturers and repair shops track and manage the availability of vehicle parts to ensure timely repairs and production.

It helps construction companies manage the inventory of tools, equipment, and materials across various project sites, ensuring timely availability and reducing project delays.

The software assists in managing the vast array of specialized parts and components needed for aircraft maintenance and production, ensuring compliance with stringent safety standards.

Retailers use it to monitor stock levels across multiple locations, optimize inventory turnover, and improve order fulfillment efficiency.

The software tracks and manages the inventory of essential drilling equipment and parts, supporting continuous operations in remote and challenging environments.

It tracks and manages medical supplies and equipment, ensuring that hospitals and clinics have the necessary items to provide patient care without delays.

It manages the inventory of network equipment and spare parts, ensuring reliable and uninterrupted telecommunications services.

The software helps manage perishable inventory, ensuring freshness and reducing waste by tracking expiration dates and optimizing stock levels.

It optimizes the storage, retrieval, and distribution of parts and products, enhancing overall supply chain efficiency and customer satisfaction.

It enables manufacturers to maintain optimal raw materials and components stock levels, ensuring uninterrupted production processes and minimizing downtime.

A mid-sized company that produces automotive parts operates out of a central manufacturing house and distributes its products to several regional warehouses in the USA. It had problems with monthly pallet displacement and loss, malfunctioning critical equipment, and inefficient inventory tracking methods, which led to incorrect inventory counts, which in turn led to overstock and stockouts.

The company sought our parts inventory software to optimize its operations in response to these challenges.

Parts inventory management software is a specialized tool designed to help businesses track, manage, and optimize their inventory of parts and components. It provides real-time data and insights to ensure efficient inventory control and decision-making.

The parts inventory management software helps reduce costs by minimizing overstocking and stockouts, which can lead to significant savings on storage and emergency procurement. Additionally, it automates manual tasks, reducing labor costs and human errors.

Yes, most parts inventory management software can integrate seamlessly with ERP, CRM, accounting, and other business systems. This integration ensures data consistency and streamlines operations across different departments.

Barcode scanning speeds up the process of updating inventory records and order processing. It enhances accuracy by reducing manual entry errors and streamlines inventory audits, making inventory management more efficient.

Multi-warehouse management allows businesses to oversee inventory across multiple locations from a single platform. It improves stock visibility and facilitates better inventory distribution and fulfillment, optimizing overall supply chain operations.

Yes, parts inventory management software can store and manage supplier details, including contact information, pricing, and lead times. This feature streamlines procurement processes and helps maintain strong supplier relationships.

Many parts inventory management systems offer customization options to tailor features and workflows to specific business needs. Customization ensures the software aligns with unique operational requirements and enhances user experience.

User access control allows administrators to assign specific permissions to users based on their roles within the organization. This feature enhances security by restricting sensitive inventory information to authorized personnel only, preventing unauthorized access and potential misuse.

Customizable alerts and notifications inform users of critical inventory events, such as low stock levels, expiring products, and order status updates. These timely notifications help users proactively maintain optimal inventory levels and avoid potential issues.

Yes, many parts inventory management software offers mobile apps, allowing users to access and manage inventory on the go. Mobile accessibility provides flexibility and convenience, enabling remote monitoring and management of inventory.

The software automates inventory tracking, reordering, and reporting, reducing manual tasks, minimizing errors, and ensuring optimal stock levels. These features improve operational efficiency, enabling businesses to focus on core activities and strategic growth.

To implement effective parts inventory management in your industry, you can rely on Aratum software solutions tailored to your business requirements to help you get started and gain visibility, efficiency, and resiliency.

Aratum is a globally recognized software provider specializing in developing supply chain management solutions. Our software solutions incorporate advanced algorithms and optimized data structures to facilitate efficient data processing and information dissemination across organizations.

Leveraging cutting-edge technologies such as machine learning and artificial intelligence, the software enables automated decision-making and real-time analytics, enhancing supply chain visibility and improving overall performance.

With a focus on delivering robust and scalable solutions, Aratum is committed to providing our clients with the tools necessary to optimize their supply chain operations and gain a competitive edge in your respective markets.

© 2024 Aratum or an Aratum affiliate company. All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of Aratum or an Aratum affiliate company. The information contained herein may be changed without prior notice. Some software products marketed by Aratum and its distributors contain proprietary software components of other software vendors. National product specifications may vary. These materials are provided by Aratum or an Aratum affiliate company for informational purposes only, without representation or warranty of any kind, and Aratum or its affiliated companies shall not be liable for errors or omissions with respect to the materials. The only warranties for Aratum or Aratum affiliate company products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. In particular, Aratum or its affiliated companies have no obligation to pursue any course of business outlined in this document or any related presentation, or to develop or release any functionality mentioned therein. This document, or any related presentation, and Aratum’s or its affiliated companies’ strategy and possible future developments, products, and/or platforms, directions, and functionality are all subject to change and may be changed by Aratum or its affiliated companies at any time for any reason without notice. The information in this document is not a commitment, promise, or legal obligation to deliver any material, code, or functionality. All forward-looking statements are subject to various risks and uncertainties that could cause actual results to differ materially from expectations. Readers are cautioned not to place undue reliance on these forward-looking statements, and they should not be relied upon in making purchasing decisions. Aratum and other Aratum products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Aratum (or an Aratum affiliate company) globally. All other product and service names mentioned are the trademarks of their respective companies. See aratum.com for additional trademark information and notices.