A good grip on your inventory corresponds to a steady financial flow in your business. Advanced technologies like AI, cloud, and automation give you absolute control over your inventory.

Aratum’s Technological Solutions gives unprecedented inventory power for an efficient, unwavering, and smooth-flowing supply chain.

Inventory Allocation

Fulfillment Automation

Low Inventory Notification

Customized Customs Declaration Value and Labels

Real-Time Shelf & Storage Visibility

Out-of-the-Box Billing and Invoicing

One-Click Generation of Pick-and-Pack List

Cloud/Multi-cloud/Hybrid Solutions

IoT Integration

Security with Identity Access Management (IAM)

An omnichannel approach is vital for customer satisfaction, as customers expect seamless access to products, offers, and support across all channels. Aratum enables you to manage your products and adjust stock distribution dynamically based on real-time demand data. This optimizes inventory levels, reduces carrying costs, and improves order fulfillment rates, allowing you to meet demand everywhere with just one click.

Streamline your order fulfillment process with automated workflows that accurately and quickly handle picking, packing, and shipping. Aratum’s inventory system reduces manual intervention and errors, accelerates delivery times, and helps maintain consistent service levels. Automation in fulfillment enhances productivity and allows businesses to scale their operations effortlessly.

Stay ahead of stock shortages with Aratum’s low inventory notification feature. It provides real-time alerts when inventory levels dip below preset thresholds. These notifications help prevent stockouts, assure timely reordering, and maintain optimal inventory levels. It minimizes lost sales and ensures consistent stock availability to keep your customers happy.

Simplify international shipping with automated, customized customs declarations and labels that comply with regional requirements. This helps avoid delays, reduces administrative burdens, and guarantees smooth cross-border transactions.

Full stock visibility lets you prioritize critical dependencies through customizable order display sequences. You can easily adapt your inventory to meet holiday demands and promotional activities with readily available kitting and bundling options.

Reduce administrative workload with a pre-built, ready-to-use solution fully integrated into a system without requiring extensive customization or setup. With customizable templates, automatic tax calculations, and payment tracking, this feature automates financial processes, minimizes errors, and ensures timely invoicing.

Boost your warehouse efficiency with our one-click pick-and-pack list generation, designed to streamline order processing for faster, more accurate fulfillment. This automated feature eliminates the need for manual list creation, reducing time spent on repetitive tasks and minimizing picking errors.

Aratum’s inventory management system offers flexible deployment options, including cloud, multi-cloud, and hybrid configurations. These solutions allow businesses to scale effortlessly, access real-time inventory data, and integrate with existing infrastructure, ensuring continuity and adaptability to changing business needs.

The system integrates with IoT devices to provide real-time inventory levels, location, and condition data. IoT sensors and trackers enhance visibility and accuracy, reducing manual inventory checks and enabling automated replenishment based on stock movement.

Protect your inventory data with robust Identity Access Management (IAM) controls that ensure only authorized users can access sensitive information. Aratum’s IAM features help prevent unauthorized access, reduce the risk of data breaches, and maintain regulatory compliance.

Efficient management of medical supplies and equipment to ensure availability for patient care while minimizing wastage and stockouts.

Maintaining optimal inventory levels of drugs and vaccines to meet patient demand, comply with regulatory requirements, and minimize expiration losses.

Managing inventory of financial products such as securities and bonds to meet investor expectations while minimizing storage costs and market risks.

Optimizing product inventory levels to meet customer demand, reduce stockouts, and maximize sales while minimizing holding costs and markdowns.

Balancing inventory levels across multiple warehouses to efficiently fulfill online orders, minimize shipping times, and improve customer satisfaction.

Proper storage and transportation of temperature-sensitive goods, such as perishable foods and pharmaceuticals, are essential to maintaining quality and safety throughout the supply chain.

Managing inventory of vehicles, spare parts, and fuel to ensure smooth operations, minimize downtime, and optimize fleet utilization.

Maintaining raw material and component inventories to support production schedules, meet customer demand, and minimize production disruptions.

Managing inventory of software licenses, hardware devices, and security tools to protect against cyber threats, ensure compliance, and maintain business continuity.

Safely storing and handling hazardous materials to comply with regulatory requirements, minimize risks to personnel and the environment, and ensure timely availability when needed.

Maintaining inventories of essential supplies and equipment for emergency response, disaster relief, and national security, ensuring readiness and resilience in critical situations.

Optimizing inventory of water treatment chemicals, equipment, and energy sources to ensure continuous supply, reduce waste, and minimize operational costs.

More Profits

A mid-sized American retail fashion company faced challenges with excess stock and loss of budget expenses. Despite investing heavily in marketing and promotional activities, the company struggled to align inventory levels with customer demand, leading to overstock situations, markdowns, and lost sales opportunities.

With Aratum’s help, the company implemented an AI-powered, cloud-based supply chain inventory management software to improve its operations.

Supply chain inventory management involves overseeing the flow of goods from suppliers to customers, ensuring the right products are available in the right quantities at the right time while minimizing holding costs and optimizing efficiency.

Effective inventory management is crucial for meeting customer demand, minimizing stockouts, reducing holding costs, optimizing working capital, and enhancing overall supply chain efficiency.

Poor inventory management can lead to stockouts, overstocking, increased holding costs, reduced profitability, customer dissatisfaction, lost sales, supply chain disruptions, and financial losses. It can also negatively impact competitiveness and brand reputation.

IoT and cloud-based technology such as inventory management systems, barcode scanning, RFID tracking, and advanced analytics provide real-time visibility into inventory levels, enhance accuracy, streamline processes, and facilitate data-driven decision-making.

Aratum’s system uses real-time data and intelligent inventory allocation to optimize stock levels, ensuring that products are always available where needed without holding excess inventory.

Aratum provides advanced security through Identity Access Management (IAM), ensuring that only authorized personnel can access sensitive data, protecting against breaches, and maintaining regulatory compliance.

Aratum automates fulfillment by generating pick-and-pack lists with one click, reducing manual effort, minimizing errors, and speeding up the entire process, which improves efficiency and customer satisfaction.

The low inventory notification feature sends real-time alerts when stock levels dip below a preset threshold, helping businesses prevent stockouts and ensure timely replenishment.

Companies can reduce excess inventory by improving demand forecasting accuracy, optimizing supply chain processes, enhancing supplier collaboration, and liquidating slow-moving or obsolete inventory. Implementing a cloud-based system is crucial to achieving these.

The implementation time for inventory management software varies depending on the size of the warehouse, the complexity of the operations, and the level of customization required. A typical implementation can take anywhere from a few weeks to several months.

To implement efficient inventory management in your business, you can rely on Aratum’s AI and cloud-based solutions to help you get started and gain business visibility, efficiency, and resiliency.

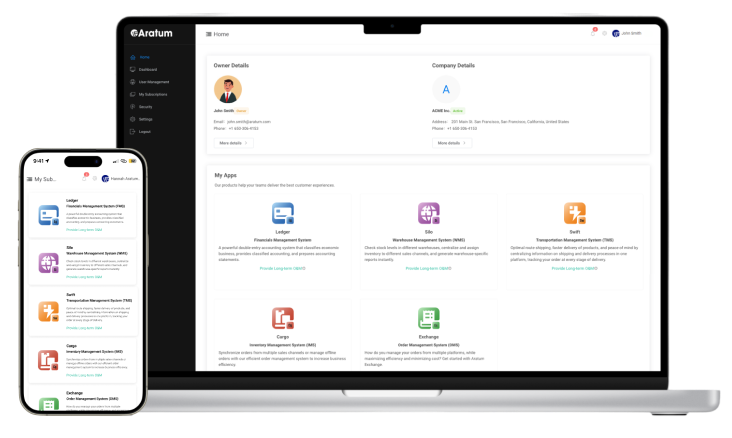

Aratum is a globally recognized software provider specializing in developing supply chain management solutions. Our software solutions incorporate advanced algorithms and optimized data structures to facilitate efficient data processing and information dissemination across organizations.

Leveraging cutting-edge technologies such as machine learning and artificial intelligence, the software enables automated decision-making and real-time analytics, enhancing supply chain visibility and improving overall performance.

With a focus on delivering robust and scalable solutions, Aratum is committed to providing our clients with the tools necessary to optimize their supply chain operations and gain a competitive edge in your respective markets.

© 2024 Aratum or an Aratum affiliate company. All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of Aratum or an Aratum affiliate company. The information contained herein may be changed without prior notice. Some software products marketed by Aratum and its distributors contain proprietary software components of other software vendors. National product specifications may vary. These materials are provided by Aratum or an Aratum affiliate company for informational purposes only, without representation or warranty of any kind, and Aratum or its affiliated companies shall not be liable for errors or omissions with respect to the materials. The only warranties for Aratum or Aratum affiliate company products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. In particular, Aratum or its affiliated companies have no obligation to pursue any course of business outlined in this document or any related presentation, or to develop or release any functionality mentioned therein. This document, or any related presentation, and Aratum’s or its affiliated companies’ strategy and possible future developments, products, and/or platforms, directions, and functionality are all subject to change and may be changed by Aratum or its affiliated companies at any time for any reason without notice. The information in this document is not a commitment, promise, or legal obligation to deliver any material, code, or functionality. All forward-looking statements are subject to various risks and uncertainties that could cause actual results to differ materially from expectations. Readers are cautioned not to place undue reliance on these forward-looking statements, and they should not be relied upon in making purchasing decisions. Aratum and other Aratum products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Aratum (or an Aratum affiliate company) globally. All other product and service names mentioned are the trademarks of their respective companies. See aratum.com for additional trademark information and notices.