Companies in the fiercely competitive supply chain industry always seek methods to enhance productivity and cut costs. One promising area for significant improvement is the use of IoT in inventory management.

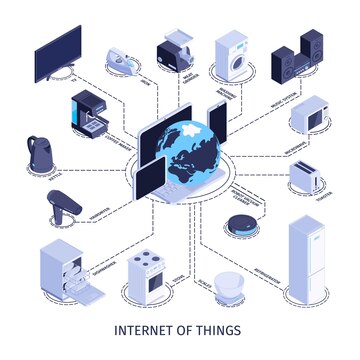

Traditional inventory management, often manual and time-consuming, can lead to inaccurate data and stockouts. The Internet of Things (IoT) offers a solution by automating and streamlining inventory processes, providing real-time data and insights. This technology helps organizations optimize inventory levels and increase profitability.

Supplier networks become robust when more data is transmitted faster and more accurately across supply chains. According to Gartner, the world’s top-performing supply chains use IoT and predictive analytics in full production environments. IoT is transforming these top-notch supply chains in every way.

As physical goods move through the supply chain, they are equipped with smart sensors as part of the IoT in the inventory management ecosystem. These sensors use the Internet to provide real-time updates on location, temperature, humidity (for cold storage), handling speed, and more.

IoT in inventory management automates and streamlines traditional inventory tracking, which is often tedious, time-consuming, and prone to human error. The seamless real-time connection between RFID tags and sensors makes it easier to identify bottlenecks, boosting productivity and reducing lead times.

In an IoT and RFID-based inventory management system, every inventory item that needs tracking is tagged with an RFID tag. Each tag’s unique identification number (UID) digitally encodes relevant information, such as the item’s model and batch number.

RFID readers scan these tags, collect data on their IDs, and send this information to the cloud for processing. The reader’s location and timestamp are also provided to the cloud, allowing it to determine the object’s location and generate a visual output of the results, displaying real-time changes.

Increasingly, online merchants use advanced tools like live dashboards and intelligent shelves to manage and maintain their inventory in real time. This approach ensures that top-selling items are always in stock and effectively meets changing seasonal demand.

Why You Need IoT In Inventory Management

The Internet of Things (IoT) is a groundbreaking innovation that accelerates the intricate digitization of manufacturing facilities and is transforming the daily operations of online businesses. With IoT, developing a smart inventory management system to track and monitor assets in real-time is now possible, ensuring stock is always available. Devices such as sensors and GPS make this feasible, increasing efficiency and reducing expenses by minimizing overstocking and stockouts.

Improved Overall Visibility

Real-time inventory tracking provides your business with complete visibility into inventory quantities, locations, and status at all times. This enhanced visibility enables better decision-making, decreases stockouts, prevents overstocking, and improves overall inventory management.

Critical Inventory Data

Traditional inventory tracking techniques rely on labor-intensive manual data entry or sporadic audits, leading to delays and inaccuracies. IoT in inventory management automates data collection, providing precise and current inventory data. This accuracy enhances order accuracy, reduces discrepancies, and increases customer satisfaction.

Greater Efficiency & Productivity

Real-time inventory tracking eliminates the need for manual counts and physical searches for inventory goods. This streamlines inventory management procedures, reduces manual labor, and frees up staff for higher-value tasks. As a result, efficiency, production, and cost savings all increase.

Faster Replenishment and Competitive Demand Planning

With real-time visibility into inventory levels, businesses can proactively identify low-stock situations and initiate immediate replenishment. This prevents sales losses, reduces stockouts, and optimizes inventory levels based on demand fluctuations. Accurate demand planning reduces carrying costs and enhances customer service.

Better Collaboration

Real-time inventory management facilitates seamless collaboration among supply chain partners. Using precise, real-time inventory information, suppliers, manufacturers, distributors, and retailers can synchronize production, improve logistics, and enhance supply chain efficiency.

Warehouse Management

Effective inventory management also encompasses warehouse management. Warehouse errors can be costly, leading to operational roadblocks and additional labor, incurring unnecessary expenses. IoT devices enhance processing speeds and overall warehouse efficiency while reducing manual labor and error rates. Businesses are equipping warehouses with IoT sensors to monitor the use and movement of materials and assets. Additionally, sensors on shelves provide management systems with real-time inventory data.

IoT and smart warehouse management help eliminate costly and time-wasting mistakes by ensuring precise tracking and continuous monitoring of inventory levels and equipment placements.

The Challenges of IoT in Inventory Management

Technology is rapidly transforming supply chain networks. The primary challenge for inventory management is the lack of sufficient information to make informed decisions. Replacing outdated systems with IoT devices enhances efficiency by improving tracking, traceability, quality control, and compliance.

In recent years, warehouses have become vital business hubs that enhance supply chain efficiency and speed. Many businesses now use IoT devices to manage inventory. However, there are considerations for IoT deployment, including investment cost, security, and scalability.

Investment Cost and Installation

It’s crucial to ensure that installing RFID tags doesn’t disrupt regular production processes, as RFID installation can be time-consuming. Additionally, initial implementation costs for IoT equipment can be high. Businesses must evaluate whether the benefits justify these expenses.

Scanning Challenges

Scanning can be problematic, especially with materials like liquids and metals, which can lead to inaccurate readings. Addressing these challenges is essential for effective IoT integration.

Security Concerns

Using technology reliant on connected networks and the internet makes systems vulnerable to cyberattacks. Business owners must implement robust security measures to protect their systems. Fortunately, advanced cybersecurity solutions, including blockchain-based IoT applications, offer multiple layers of security.

Decreasing Costs and Growing Adoption

Despite these challenges, the cost of IoT technology continues to decline as its adoption becomes more widespread. IoT devices are rapidly replacing traditional inventory management methods, providing an affordable and efficient option for many businesses. These devices generate substantial real-time data, which companies use to optimize supply chain, inventory, and logistics operations.

Implementing IoT in Inventory Management

To maximize the effective and secure use of IoT in inventory management and logistics, follow several best practices. Start by determining objectives and key performance indicators (KPIs) that align with your company’s goals and clients’ expectations. Then, choose the best IoT platforms and devices, test and verify solutions, and continuously monitor and enhance them.

Compatibility and Integration

Ensure the IoT devices are compatible with your existing inventory management systems. Real-time tracking and reporting should be seamlessly connected to enable smooth data flow between IoT devices and the inventory management system.

Strategic Device Placement

Proper placement of IoT devices is crucial for reliable data collection. Position devices like barcode scanners or RFID readers in critical areas to ensure accurate data acquisition. Follow installation instructions to guarantee optimal reliability and functionality.

Practical Applications of IoT in Inventory Management

Weight Sensors

Weight sensors placed beneath merchandise bins can monitor inventory levels and automate counts. These touchless IoT devices can initiate replenishment when minimum levels are reached and can be managed remotely. They are suitable for a variety of items, including cardboard boxes, registration plates, fasteners, medical supplies, and hotel linens.

Electronic Shelf Labels

Low-energy Bluetooth beacons on electronic shelf labels (e-labels) enable two-way communication about any product. Users can initiate orders by pressing a button on the e-label, and suppliers can inform the tag when the item is on order, preventing further procurement. The tags also provide details about the vendor and product.

Conclusion

IoT is revolutionizing inventory management with increased intelligence and efficiency, helping businesses stay competitive in the fast-evolving online market. By transforming inventory management into a strategic asset and value driver, IoT gives online merchants a significant competitive edge.

Aratum has the tools to make your business IoT-ready. With tech-driven solutions, you can upgrade your inventory management and receive real-time stock updates. Strategic planning is easier when you have access to the correct data. Sign up to get instant access.

The cover photo of this article was sourced from freepik.