Why is product serialization crucial in the food and beverage industry? Knock-offs or counterfeit products come in many forms. Usually, we only think of expensive goods such as designer handbags or consumer electronics like smartphones when it comes to counterfeit goods. When fake products are circulated online, 64% of consumers lose trust in a brand. Apart from that, you’ll have to deal with the fallout of products not part of your product line or those you have not authorized. This can destroy your ability to expand into new markets and reach potential customers.

Billions to trillions of dollars are lost, and millions of jobs are lost because of counterfeit products. And there’s nothing sacred to these unscrupulous players. Today, these profiteers are just as likely to tamper with products from the food and beverage industry. These frequently malicious actors want to earn an easy buck at the expense of consumers throughout the food and beverage supply chain.

Food fraud, falsification, and adulteration may go unnoticed when there isn’t real-time transparency during multiple product deliveries. From manufacture to packaging and delivery, every step of making a food product presents a chance for tainted goods to enter the supply chain. As a business owner, you’ll want to provide only the best products for your customers to enjoy with peace of mind.

- Why Product Serialization Matters in the Food and Beverage Industry

- How Product Serialization Works

Product Serialization and Numbering

Before we move on to the importance of product serialization and how it works, let‘s discuss the nitty-gritty of product numbering to trace products in the food and beverage industry.

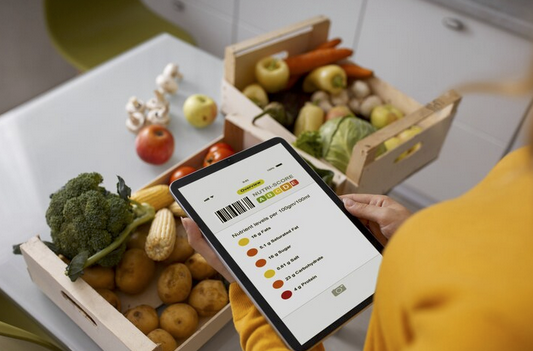

We’re sure you’ve received packages with stickers and numbers. These numbers are plastered on the labels and boxes of most manufactured products and commodities. They’re as ubiquitous as bar codes and product descriptions. Product serialization creates a unique identifier for food products before they are distributed and prints that code on the label or package.

While serialization may vary slightly between countries, all labels typically contain a distinctive serial number, identification code, batch number, and expiration date.

Serialization doesn’t always have to adhere to a rigid numerical pattern, although it is frequently described in terms of serial numbers.

Serial numbers are apparent on many of the items you own. Unit serial numbers are printed on various things, including jewelry, smartphones, musical instruments, computer hardware and software, home appliances, automobiles, etc. Individual components may also have serial numbers for electronics or appliances with numerous separate parts.

Aside from serial numbers, some products will include model numbers. The model an item belongs to, not the specific unit is identified by its model number.

A Stock Keeping Unit (SKU) is another tool for tracking and tracing merchandise at the store level. This, however, is a location-specific number that is only used at the store where it is being sold and has nothing to do with a particular saleable unit of an item.

Serialization enables manufacturers and retailers to use machine and human-readable codes. These codes track products’ origins and identify which suppliers handled the products or packaging. They can also determine the precise components or ingredients in the finished product. Through end-to-end traceability, business owners can quickly pinpoint an item’s history.

Why Product Serialization Matters in the Food and Beverage Industry

The relevance of product traceability has grown due to the food industry’s focus on quality assurance. Tracing and recalling the source of potential contamination or raw materials hazardous to health has become a much bigger task as the supply chain system is now becoming more complex. Serialization in the food sector is a practical solution to this issue. Every production and logistical chain step, from farm to fork, can be recorded and retrospectively regulated, all thanks to serialization.

Proper food labeling and serialization have two benefits: First, accessible data tracking helps swiftly and efficiently remove faulty products from the market. Second, if information about ingredients is correctly recorded and conveyed at all processing stages, it is faster to prevent health issues brought on by food allergies or intolerances.

Counterfeit food products violate intellectual property rights, whereas substandard food items do not follow production, packaging, storage, or distribution laws. There have been notable scandals related to poor food and beverage standards. Examples include melamine-contaminated baby milk and unpasteurized fruit juice, which cause major health concerns. These kinds of issues have the potential to spread to other countries and can affect consumer confidence. A poor brand reputation, in turn, affects companies’ bottom line.

Manufacturers and distributors can benefit from serialization in various ways. By tracking data, they may adhere to industry standards, making workflows more predictable and transparent. Additionally, software for print control and monitoring used for product identification reduces the possibility of errors.

Clear Supply Chain Visibility

The supply and logistics systems in the food and beverage sector are among the most intricate. As a result, producers require distinctive product identifiers to track the locations of the components and ingredients in their supply chain.

With serialization, food and beverage companies may monitor and manage their complex logistical processes more effectively and efficiently. Manufacturers can better understand their procedures across all facets of their business.

Authentication to Combat Counterfeiting

Unfortunately, counterfeiters and criminals frequently take advantage of consumers’ food and beverage needs. They offer “substitutes,” typically fake, while masquerading as authentic ones.

Such items, however, fail to meet the essential compliance and quality requirements, putting consumers in danger. Product serialization is crucial since it enables concerned parties to distinguish between authentic products and fakes.

The presence or absence of specific goods in a batch you ordered can be immediately identified using scannable codes.

Coordinated Product Recalls

Food and barrage products can have unforeseen problems that necessitate removal from the market. Thanks to serialization, manufacturers can track and trace faulty batches in collaboration with governmental organizations.

Businesses can rely on their tracking systems to follow the items from their origin in the factory to store shelves worldwide. A well-executed product serialization makes these recall efforts more effective.

Data Analysis and Forecasting

Business owners can use serialization to label and trace products from when they leave the facility until sold. This procedure allows manufacturers to monitor various batches to determine and study consumer responses.

This information helps food producers better comprehend the market demand for their goods. A thorough understanding of demand will enable them to acquire the raw materials required for the subsequent manufacturing run to satisfy orders.

How Product Serialization Works

Advanced serialization has been mandated and successfully implemented in other sectors, such as the highly sensitive pharmaceutical industry. This has made it possible to fully track and trace drugs from the manufacturer to the point of patient dispensation. A similar approach can benefit food and beverage supply chains by providing greater visibility and product security.

A digital data system serializes and registers each product you sell. Every order obtains authorization from the electronic data system when the product meets the customer. The system then associates it with the customer and completes the sale.

The three phrases above explain the most straightforward traceability system. Even at this level, a system can stop criminal activity. However, implementing product serialization is more than just applying a new barcode to an item.

To provide all the primary benefits listed above, labels must be individually coded and remotely trackable at every point in the supply chain.

Before distribution, products are given radio frequency identification (RFID) tags to make them scannable at all points in the chain of custody. The data retrieved from the scan is stored in a supply chain management database, a cloud-based online system driven by blockchain technology.

A product is scanned each time it is transferred. Brands have complete visibility of how the item got to its destination and can use this information to detect counterfeiting and other suspicious activities. With each position recorded, a digital trail is built.

RFID tags are now combined with Internet of Things (IoT) sensors and analytic software platforms. It can provide specific insights to businesses looking to optimize costs and increase operational efficiency and accuracy. Blockchain technology is gaining more traction, strengthening accuracy and fraud prevention by guaranteeing an unchangeable data trail.

A food and beverage business may respond to complaints faster when it has more specific information on hand. Such information is immediately available on demand during a product recall or a query regarding an item’s quality.

Thanks to data acquired via serialized tags, you can get unmatched insights into the product journey from floor to shelf and beyond.

However, all supply chain stakeholders must agree to exchange serialized data for this to work correctly. Manufacturers should be the first link in the chain because they assign serial numbers. Data is exchanged once the product reaches the next downstream point, and so forth. This ensures reduced returns and customer confidence.

Silos between points in the supply chain are eliminated when data is decentralized, as in a blockchain database. This makes it easier for businesses to guarantee quality despite reliance on distributors and carriers who occasionally control a brand’s products.

All parties can access the data in a blockchain database. Information quickly spreads across the supply chain and ensures that standards are maintained at every stage.

Serialization offers growing businesses a way to use all the technological advantages. Manufacturers who can reassure their customers of authenticity and sustainability are ahead of the curve. And that’s always a good thing, even as counterfeit enterprises flood the market with fake goods.

Your customers can also check for product quality themselves using QR codes on product tags. These can be scanned to display specific information, such as serial numbers, product verification, warranties, etc. More meticulous customers can even inspect the names of the factories that made the components and the individuals who put them together.

Adopting product serialization allows food and beverage producers to safeguard their products by identifying and controlling risks from counterfeit products. The added security can help establish a competitive advantage and foster consumer trust. Being proactive will allow you to collect more detailed data, aiding reverse logistics and recalls. Additionally, precise visibility of products and quantities tightens your inventory control.

Aratum helps you manage your supply chains smartly. Our complete suite of digital logistics solutions makes product serialization possible. From automation to complete supply chain visibility, request a demo today to find out how we can assist your business.

The featured photo of this article was sourced from freepik.