If the engine doesn’t run, the work’s not done.

Manufacturing technologies that go through unexpected failures can cause companies serious problems, and one of the leading causes of lost productivity and money in the supply chain is downtime. Your products must keep moving and are replenished regularly. You don’t want downtime, as these disastrous incidents cost businesses about $50 billion annually.

The consequences of necessary machinery suddenly running at half capacity or not at all vary from production slowdowns to total functional failures.

Enter artificial intelligence (AI), the technology slowly becoming ingrained in our daily lives. AI is transforming several facets of how we work. AI can improve efficiency in various fields, from automated shopping services to drone deliveries and predictive text completion.

Artificial intelligence has been a game-changer in supply chain management and logistics and represents AI’s evolving function in predictive maintenance. Businesses can gather historical and real-time data to predict errors before they occur. Staff can take preventative measures by utilizing machine learning (ML) algorithms as the foundation for broader AI frameworks.

- How AI Predictive Maintenance Works

- Implementing AI Predictive Maintenance in Your Supply Chain

Predictive maintenance, as used in AI and machine learning, is the capacity to use large amounts of data to identify and resolve problems. It prevents said issues from causing malfunctions in systems, operations, services, or processes. The market for predictive maintenance solutions has expanded rapidly. Projections indicate it will reach a market value of $12.3 billion globally by 2025.

Businesses with robust predictive maintenance systems can forecast when and where service breakdowns could happen. Data allows maintenance teams to take action to address problems before they cause potential service disruptions.

Companies can solve typical challenges within the supply chain by using artificial intelligence.

Logistics technology improves efficiency, accuracy, and decision-making capabilities. With it, business leaders can proactively address maintenance issues before they become serious problems.

How AI Predictive Maintenance Works

Artificial intelligence systems are made to resemble the human intellect in particular jobs or tasks. It means that these responsibilities can be automated rather than performed manually.

In predictive maintenance, AI tools can examine the state of the equipment’s current functionality and search for potential issues in the future, even if there haven’t been any apparent problems. AI predictive maintenance systems can detect subtle changes in machine performance by comparing current data to baseline metrics. By identifying these early signs of maintenance needs, teams can proactively replace specific parts before they fail.

Two essential elements for properly operating AI systems are machine learning algorithms and reliable data access.

Good data is a priority. AI systems need continuous access to both historical and current data to assess machine performance. This data helps process details about a particular machine’s functionality and any information on deviations.

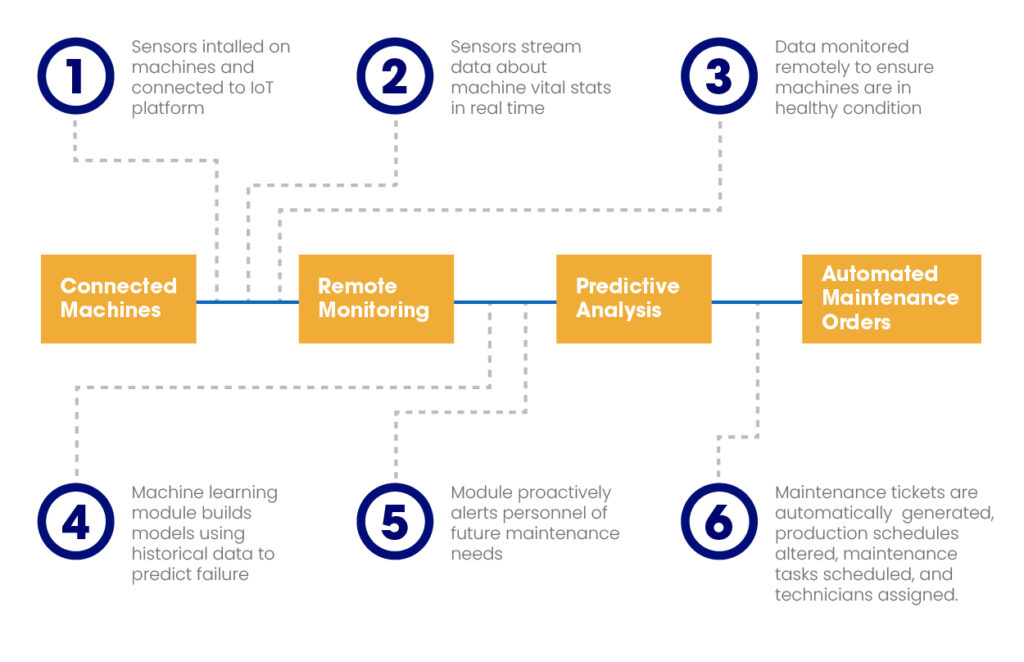

The Internet of Things (IoT) is also closely linked to AI’s capacity for predictive maintenance. With the correct ML algorithms and AI frameworks in place, these “smart factories” provide vast amounts of information to gather and use for predictive maintenance.

AI-based predictive maintenance looks ahead to what could happen if present conditions stay the same or what might happen if things change. Contrast this with traditional maintenance, which concentrates on current operations. Manual maintenance relies on historical data only to schedule repairs based on it. Meanwhile, AI predictive maintenance enables businesses to reduce the possible effects of prospective problems by proactively addressing them before they arise.

Lower Maintenance Costs

Addressing maintenance issues proactively incurs costs, but these are significantly lower than the expenses of post-failure repairs. When issues are resolved after a failure, additional costs arise from reduced product output and production line shutdowns.

Improved Processes

AI enhances overall production procedures in two key ways. First, AI solutions can identify areas that would benefit from targeted improvements, leading to better production outcomes. Second, AI technologies can detect process trends that cause inefficiencies and provide solutions by utilizing data from IoT-connected devices and sensors.

Teams may more easily develop effective maintenance programs using AI to evaluate performance over time and identify failure points.

Longer Equipment Lifespan

Unexpected and significant equipment malfunctions often require more than just costly repairs; they can necessitate expensive replacements for manufacturing machines. But with AI support, businesses can prolong the lives of their equipment and proactively handle new problems.

Implementing AI Predictive Maintenance in Your Supply Chain

You have now learned about the advantages of using AI predictive maintenance. However, it’s not the endpoint. Establishing a successful AI predictive maintenance program will require an upfront process investment that includes data monitoring, ongoing evaluation, and training.

As sophisticated supply chain technology develops, an increasing number of businesses across all sectors are expected to take a strategic and preemptive approach to maintenance. Here are tips that make a successful implementation:

Have a Skilled Support Team

When creating an AI predictive maintenance model, it’s best to use the best team to test and analyze for better outcomes. Establishing a cross-functional team, including experts and upper management personnel, is imperative to creating the support staff for your program.

Consider engaging with an independent vendor that can help with the implementation process, provide knowledge, and assist you in reaching your company’s goals and objectives. Seek out expert advice if you lack skilled staff to support program implementation. Certain consulting organizations provide highly professional services. Logistics software suppliers can also possess the knowledge and abilities to offer advice.

Identify Critical Machinery and Equipment

Every predictive maintenance program starts with creating a list of essential machinery and equipment. First, determine which assets have seen the most significant losses. Then, give those assets top priority while building your database. When your new system is deployed, essential asset maintenance needs will be met.

Ensure Software Connectivity with Machines

You must purchase or install the necessary IoT-enabled sensors and systems to monitor important conditions, parameters, and alarm codes. You can also leverage and link to already-existing control systems or machine intelligence.

Wear and tear, idle hours and power consumption are a few examples of crucial data points.

The equipment and vital assets you decide to monitor will be the focus of the data collection process.

Integrate Computerized Maintenance Control Software

Establishing cloud-based computerized maintenance control software (CMMS) with AI, ML, and remote data collection capabilities will enable you to create a precise predictive maintenance model.

Remember that your selected CMMS system will be the foundation of your AI predictive maintenance implementation procedure. IoT enables real-time monitoring of vital machinery and equipment, suggesting maintenance schedules and offering insightful analysis of gathered IoT sensor data.

Provide Staff Training

Support personnel and other staff interacting closely with your CMMS software and vital assets must receive relevant training. Training lowers the possibility of poorly implemented software resulting in inadequate maintenance and response times.

Maintenance staff and technicians frequently receive little to no additional training beyond the initial onboarding from a software vendor. Depriving support personnel of essential training can adversely affect the effectiveness and success of a novel AI predictive maintenance initiative.

Review and Monitor Data

Before launching a more extensive predictive maintenance program, monitor your initial batch of assets over time. When the final implementation is carried out, the data gathered will serve as the foundation for the maintenance program. Setting clear objectives and important KPIs will be necessary for this procedure to gauge performance levels.

Knowing your present performance levels and scores for any KPIs you want to raise is essential. Before you begin, you must identify where your KPIs stand so that you can gauge post-implementation outcomes and have actual data to compare.

Conclusion

Industries are recognizing AI’s critical role in reducing losses and transforming maintenance tactics as the need for predictive maintenance processes grows.

AI predictive maintenance is challenging to implement appropriately. It requires a thorough planning process, integration with current assets, and training staff on the new technology. However, overcoming these challenges helps build a more sustainable future for your business. Scale more effectively with lower energy consumption and a longer usable life for equipment.

Aratum is a cloud-based supply chain management software using AI to simplify operations. Get real-time data on logistics performance to help you identify where to begin predictive maintenance. Book a demo and learn how easy integrating our services into your process is.

The featured photo of this article was sourced from DC Studio on freepik.