The general outlook of international supply networks has faced disruptions for several years. The US-China trade conflict, the COVID-19 pandemic-era consumer goods boom, and the Russia-Ukraine war have been among the most notable. Natural catastrophes, bankruptcies, and operational challenges have also caused supply chain interruptions.

Operationally, supply chain activity has mostly stabilized in 2023. However, the forecast for the supply chain industry in 2024 is affected by many significant concerns in industrial policy, labor action, and environmental policy execution.

The intricate web of supply chains is the backbone of economic ecosystems. Unprecedented challenges and transformations in supply chain management impact world economies.

Disruptions caused by external shocks to integrating advanced technologies are some of the multifaceted challenges businesses must unravel as they optimize their supply chains. Navigating this web of challenges can give companies a comprehensive understanding of supply chain management’s current state of affairs. With better awareness and knowledge, stakeholders are empowered to effectively adapt and fortify their supply chain strategies for the future.

In this article, we’ll dive into:

1. Four Challenges of Supply Chain Management to Watch Out for in 2024

2. Three Strategies to Overcome Challenges of Supply Chain Management

Four Challenges of Supply Chain Management to Watch Out for in 2024

Businesses are shifting their strategy to proactive preparedness and risk management rather than reacting to challenges. The deglobalization movement is exacerbating the challenges of supply chain management. Supply chain disruptions and logistics affect more than corporate control and national boundaries.

To better understand these issues, we must first review the fundamentals of supply chains. These dynamic ecosystems include sourcing, planning, manufacturing, delivering, and returning goods and services. Global supply chains form a complex network that powers economies and promotes innovation and progress. However, this interconnectedness also creates risk, which paves the way for the issues listed below.

Inflation

Inflation consistently affects supply chains. During the epidemic, the global supply networks experienced heightened demand for consumer goods, complicating fulfillment due to disruptions caused by global lockdowns. This situation also escalated manufacturing and shipping costs.

Challenges such as pandemic-related labor scarcity and stringent health regulations continue to plague supply chain management. Persistent labor scarcity causes decreased production rates, delayed distribution, and postponed deliveries, which lead to unhappy customers.

From an economic standpoint, growing labor, freight, and raw material costs are unlikely to drop to pre-pandemic levels and continue to impact manufacturing costs.

An estimated 2.9% rate rise is anticipated in supply chains in 2024 This acceleration is due to continuous shifts in the geopolitical and economic markets, a new standard in supply chain cost pressures, and enduring supply chain disturbances. The inflationary climate has significantly altered the dynamics of supply chain operations.

Climate Change and ESG Compliance

Climate change-related weather events pose a real danger to supply chain operations. Wildfires, floods, and hurricanes may obstruct traffic and harm infrastructure. Businesses must modify their supply chain plans to consider both the short-term effects of weather and long-term sustainability measures.

The increased awareness of environmental, social, and governance (ESG) concerns will directly impact the supply chain. That’s all thanks to more stringent laws about unfair practices and transactions and the imposition of more severe penalties.

Sustainable practices are becoming more widely recognized as an essential tactic for reducing the dangers related to climate change. However, this requires large initial outlays, which may be difficult for businesses with few resources.

Companies are continuously urged to adopt a sustainable strategy and consider its environmental impact when working with suppliers. In today’s market, companies are expected to uphold sustainable practices across their supplier network as investors and customers demand.

Cyber Threats

As a result of the development of digital technology, supply chains are now more at risk of cyber attacks.

As cyber threats evolve rapidly, particularly in interactions between businesses and third-party suppliers, caution is important. With increasingly integrated global supplier networks, one must be wary when sharing confidential data.

Due to their complicated structure and frequent involvement by several third parties, hackers find these networks to be prime targets as they lack traceability and transparency.

Prominent events such as the Colonial Pipeline and SolarWinds hacks expose the possible repercussions. To safeguard operations from cyber threats in 2024, stakeholders must invest significantly in incident response plans, staff training, and robust cybersecurity measures.

Geo-Political Conflicts

Supply chain disruptions are mainly caused by global political upheaval. High-profile disputes, such as the trade war between the US and China, the conflict between Russia and Ukraine, and the recent Gaza-Israel conflict, impact economies.

The unstable operating environments brought about by these geopolitical dynamics cause supply chains to become less efficient and more complicated. They can intensify tensions across borders and influence international logistics channels.

RELATED READ: 2024 Supply Chain Industry Trends: 4 Must-Know for Managers

Three Strategies to Overcome Challenges of Supply Chain Management

Businesses can keep operations going despite the challenges of supply chain management. Maintaining resilience means avoiding undue dependence on a single supply source.

Companies may make more adaptable decisions and manage resources within their supply chains more effectively by diversifying their supplier base. It allows them to remain proactive in the face of uncertainties.

Supply chain agility may be improved by utilizing AI and predictive analytics technology. By promptly identifying the most advantageous connections in the supply chain, companies can reduce risks and adapt better to evolving conditions.

Greater Supplier Transparency and Visibility

Limited visibility across the layers of a supply chain profoundly impacts businesses. This can be especially problematic when complying with regulations and identifying and reducing supply chain risks.

Eliminating the Tier 1 visibility barrier enables companies to scrutinize their extended supply chain thoroughly. By vetting all partners, businesses gain deeper insights into the root causes of issues, identify emerging risks downstream, and advance ESG objectives with enhanced traceability and transparency.

Control towers and digital twins are examples of technology solutions that help with supply chain visibility. You can discover crucial sub-tier supplier links, identify shared sub-tier suppliers, and pinpoint industrial locations. It can also help you understand your organization’s supply chain’s breadth. Furthermore, they can strengthen the supply chain’s resilience when widely used.

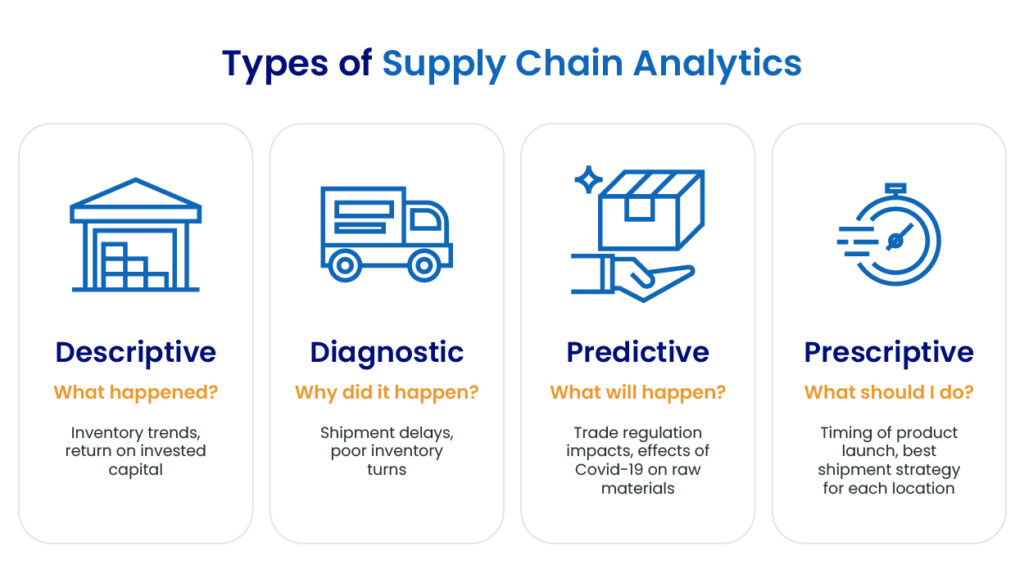

Data Analytics for Forecasting and Planning

Factors like consistency, cadence, quality, and data availability are essential in the supply chain. Supply chain managers need to handle the complexity of their data environment to improve operations and make wise decisions.

A case-driven approach to data quality is best for proactively handling the challenges of supply chain management. Organizations may enhance their datasets progressively by concentrating on specific use cases and prioritizing data quality improvements.

Develop a focused data roadmap emphasizing value creation. Connect data initiatives directly to tangible outcomes like cost reduction, productivity gains, enhanced customer satisfaction, and innovation. Ensure every data collection and analysis effort aligns with a specific objective.

Leverage Generative AI

A type of artificial intelligence called generative AI (GenAI) holds the potential to transform procurement, logistics, and supply chain management completely. Compared to earlier machine learning methods, software engines powered by GenAI can process bigger data sets and analyze nearly indefinitely complicated sets of variables. Additionally, GenAI is capable of self-learning. It can teach itself about the subtleties of any particular business’s supply chain ecosystem, enabling it to improve and hone its analysis over time.

There is a long list of potential applications for GenAI. It can streamline and improve manufacturing production workflows and ensure procurement and regulatory compliance. GenAI may facilitate virtual logistics communication by assigning virtual assistants to address fundamental questions and deliver prompt answers.

Conclusion

The risk environment changes quickly as 2024 progresses, bringing new opportunities and challenges to supply chain management. Adaptability and proactive risk management are critical components of organizational resilience in this changing environment.

As supply networks face multifaceted challenges of supply chain management, businesses must remain vigilant and adaptable. Enhancing risk management practices and exploring novel pathways are crucial for growth and innovation within the globally interconnected supply chain ecosystem.

Aratum keeps your eCommerce business ready to handle all the challenges of supply chain management in 2024. With a central console that syncs all your supply chain data in one place, being flexible and agile has never been easier. Book a demo to see how our products can impact your business.

The featured photo of this article was sourced from freepik.