Planning with some degree of assurance has become a distant memory for many modern companies. Demand-driven businesses must work even harder to meet known client needs in increasingly short time frames.

Global supply networks have seen unprecedented strain due to the growing issues they faced in recent years. From the COVID-19 pandemic to the Ukraine-Russia conflict, these events have created a perfect storm burdening supply lines.

Businesses may overcome these obstacles by implementing agile supply chains. Since 2019, the average cost of shipping worldwide has more than doubled. Climate change and increased geopolitical rivalry between the US and China present immense disruptive potential for international firms.

Enterprises must prioritize building resilient and agile supply chains in light of the growing threat of an intricate web of interconnected risks.

- Benefits of Adopting an Agile Supply Chain

- Five Strategies to Build an Agile Supply Chain

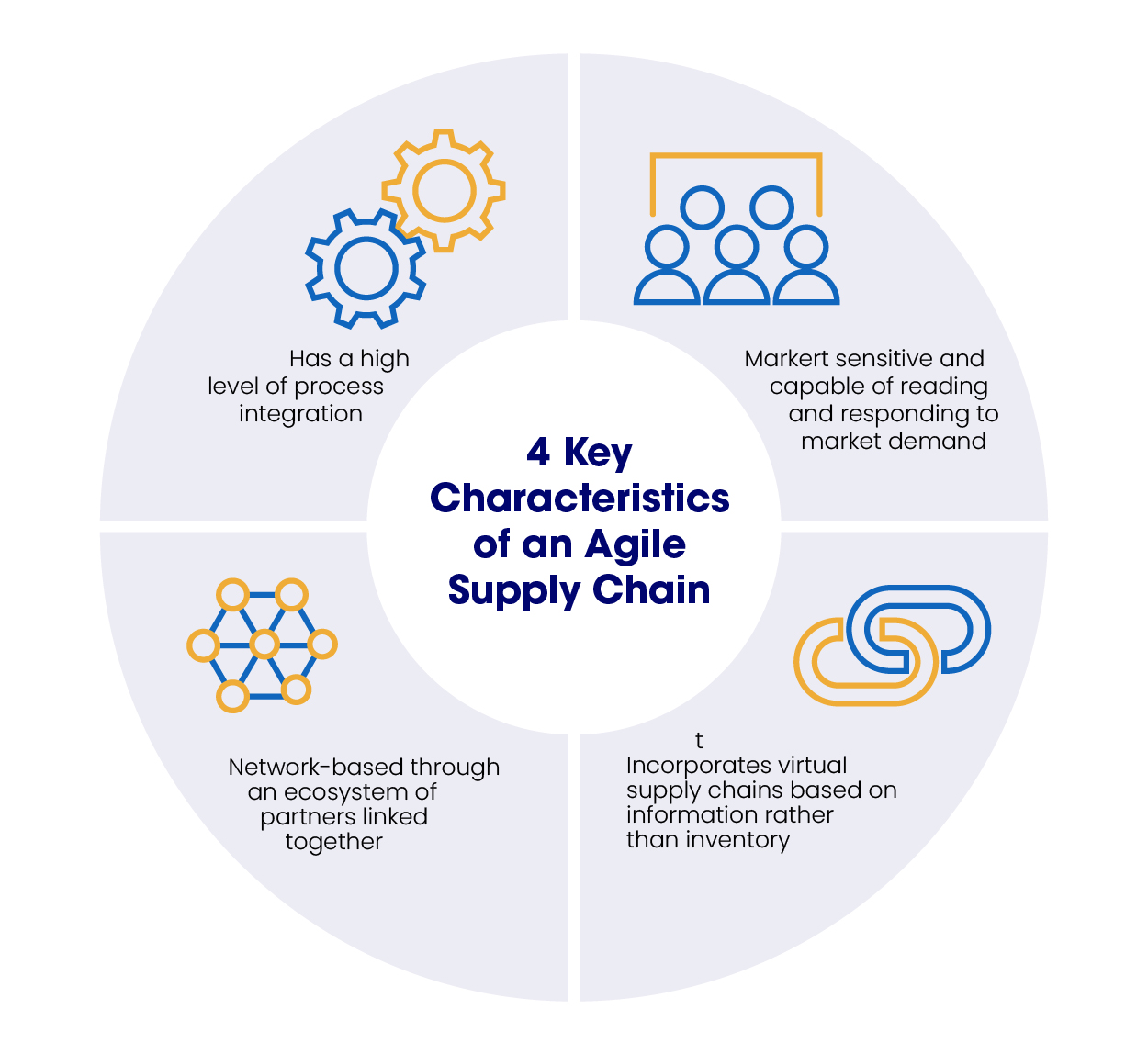

Agile supply chain management prioritizes flexibility, adaptability, and the capacity to react quickly to changes in supply and demand. It makes it suitable for dealing with an unpredictable market environment. Agile practices are predicated on ideas that lessen a system’s susceptibility to outside influences. Their main goal is to reduce the possibility of significant supply chain disruptions.

Although each agile approach is distinct, it is always built on a limited set of fundamental techniques. These include developing a large network of backup and contingency vendors utilizing creative inventory management systems. It’s also essential to use real-time data to make the best judgments at any given time. All these are needed to foresee the future with the highest degree of certainty.

Supply chain agility is more than just a fad. Many business leaders see it as the key to long-term success. Maersk reports that 57% of businesses want to increase supply chain resilience through investments in strategies that improve agility. The fact that just 27% of companies think their supply chains are flexible enough to accommodate changing business models makes this dedication to the cause of agility all the more critical.

Benefits of Adopting an Agile Supply Chain

Agile supply chain management has both short-term and long-term advantages. Businesses implementing an agile strategy in their supply chains can swiftly adapt to market changes. This adaptability might mean the difference between success and failure in this incredibly competitive market. Agile supply chains have the potential to reduce costs, boost production, and enhance efficiency over time.

Consistently Meet Market Demand

One of the main advantages of an agile supply chain is the ability to reliably satisfy customer demand for quick, reasonably priced shipments, even with varying order volumes. Careful supply chain planning and execution are practically required to keep up with constantly shifting market needs.

Building supply chain agility requires devising several strategies to guarantee client demand satisfaction in the face of unforeseen demand shifts or possible disruptions.

Agile supply networks can provide precise, instantaneous insight into demand. The data comes from software that gathers information from each supply chain link and applies sophisticated analytics to provide projections. Agile supply chains have streamlined manufacturing procedures and are partnered with several manufacturers or suppliers. Greater inventory and replenishment transparency allow them to operate with little stock. This all results in the ability to swiftly increase or decrease output in response to changes in demand.

Reduce Inventory Holding Costs

An agile supply chain helps businesses reduce the possibility of producing goods that don’t match consumer demand. This results in lower inventory levels and cheaper carrying and storage expenses. An agile supply chain may assist businesses in lowering inventory levels and increasing efficiency. Doing so cuts down on inventory costs and improves cash flow. Your supply chain will be able to create smaller batch sizes and perform more frequent deliveries.

Increase Flexibility and Efficiency

An agile supply chain may improve flexibility by enabling businesses to respond promptly and without delays. Businesses might shift toward agile processes to adjust to emerging trends and tailor their supply chains to their requirements. With flexibility, supply chain organizations may more easily implement changes and better position themselves to meet market demand.

You can facilitate swift changes to the current process without disrupting other business areas, improving overall operational efficiency. Businesses may adjust their output to suit present demands using real-time data. This cuts down on waste and saves money on other expenses like storage.

Five Strategies to Build an Agile Supply Chain

A successful, agile supply chain can reliably meet demand. Precise prediction necessitates examining the diverse factors influencing an enterprise’s supply chain operation. It could range from basic seasonal demand to intricate cash flow projections influenced by several variables. This makes it possible to effectively manage capacity, allocate resources where required, and manage inventories following demand.

1. Implement Demand Forecasting

Investing in demand forecasting software that uses predictive analytics, artificial intelligence (AI), statistics, and modeling is in your best interest. Gain the ability to evaluate large data sets and develop flexible supply chains.

Predictive analytics-enabled inventory management and demand planning software yield more precise estimates of customer demand. Get a better understanding of the trends behind your typical consumer behavior and stock replenishment requirements. You can prevent stockouts and excess stock by precisely allocating manufacturing resources and inventory levels to match demand with these estimates.

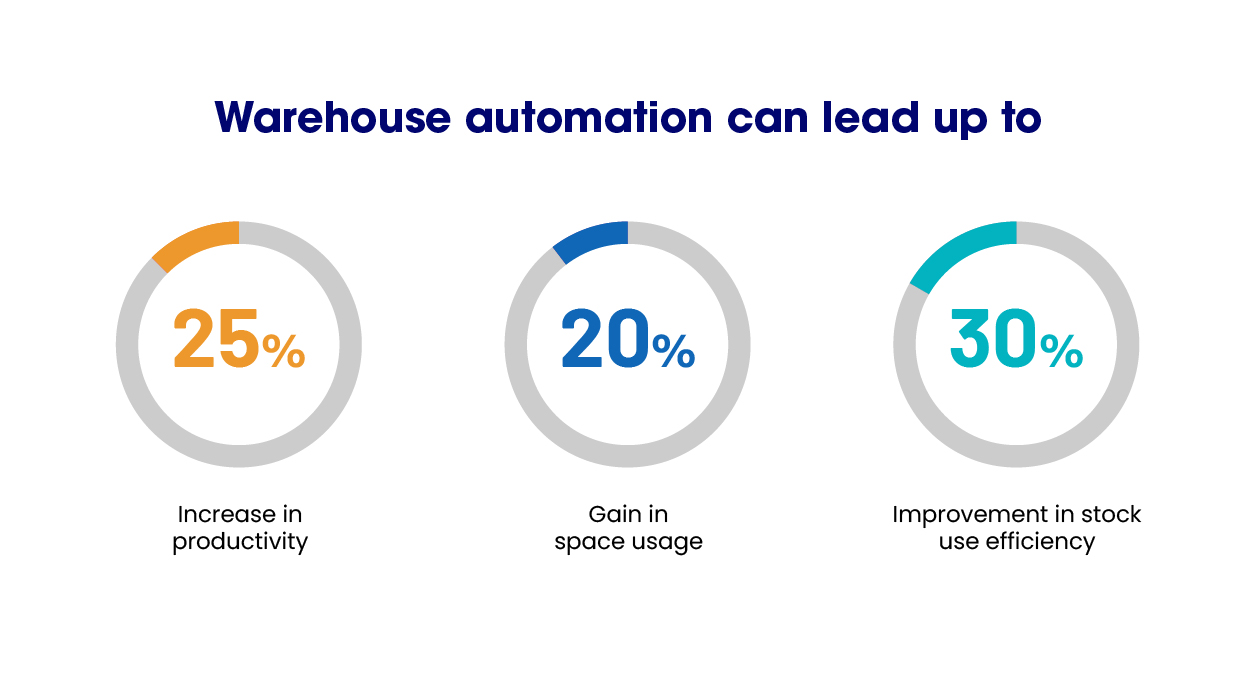

2. Warehouse Automation

When warehouse activities are automated, your supply chain can respond more quickly to changes in supply and demand. Order processing, which includes picking, packaging, and shipping, may be automated using a cloud-based warehouse management system. Smart shelves and sensors can automatically track inventory levels and movements. On the other hand, autonomous mobile robots automate processes like order picking and cargo unloading.

Automating these warehousing operations might enable a distributor to send its typical order nearly a day faster. You can satisfy any unexpected increases in demand. Compare it to slower, manual warehousing procedures that could lead to lost potential income.

3. Leverage Real-Time Data

Agile supply chains transmit real-time data across the network. This provides easy and frequent communication between partners and suppliers in production, shipping, and distribution. This communication is best achieved using a cloud-based supply chain management platform. All participants in the supply chain can proactively make decisions that impact every process. For example, a manufacturing facility produces and packages goods in three days instead of the expected two days. As soon as the deviation is identified, its software system instantly sends notifications. Logistics providers are immediately informed, allowing them to gather goods for shipping at a designated time and date.

4. Set Up SKU Reorder Points

Utilize historical inventory and sales data to predict when to reorder inventory at the SKU level. Maximizing this allows you to replenish inventory promptly, preventing stockouts and delays in retail fulfillment. Potential growth should also be considered when determining how many units of each SKU you should purchase.

Here’s a simple formula you can use to determine the SKU reorder points for products that you sell:

SKU Reorder Point = (average daily sales x lead time in days) + safety stock

Using inventory software automates this computation, integrating historical and sales data in every calculation. This automation enables faster and more efficient responses to events, such as increased seasonal demand for specific products.

5. Partner with 3rd Party Logistics

Increase supply chain agility by utilizing the capabilities of third-party logistics (3PL) providers. These providers offer services such as outsourced fulfillment, shipping, and warehousing. These are great when trying to scale operations without making a substantial investment. However, managing your warehouse network, making technological investments, and enhancing operations take time and money. While these initiatives drive efficiency, they don’t increase income immediately.

For instance, a 3PL with fifteen warehouses across the US can collaborate with a retailer with four warehouses. In the case of a spike in demand in the Southwest or bad weather in the Northeast, you may have the option to ship from other areas.

By collaborating with a 3PL, you can leave the task of enhancing supply chain agility to the experts. This will free up your attention and time for other business-critical responsibilities that only you can handle.

Conclusion

An agile supply chain is essential in light of the rapidly changing business environment and unanticipated interruptions. Seventy-five percent (75%) of supply chain experts resolved to modify their procedures based on the lessons learned during the COVID-19 pandemic. Implementing methods that increase adaptability and responsiveness is more important than ever.

Organizations can adapt and succeed in today’s changing markets by utilizing data independence, time-saving automation, and real-time insights. Issues can be resolved much faster through frictionless communication and committed support. This guarantees seamless operations, improved customer service, and a competitive advantage.

Adopting technology and a comprehensive strategy empowers people and optimizes procedures for resilience. These are the pillars of a successful, agile supply chain.

Aratum is supply chain management software that supports an agile supply chain. With simple yet effective technology, you can get full visibility throughout your supply chain. Great for businesses of all sizes, book a demo today.

The featured photo in this article was sourced from aleksandarlittlewolf on freepik.