As your business grows, challenges may arise, affecting your inventory, deliveries, finances, and other warehouse operations. An AI and cloud-based warehouse management system can help address your company’s growing pains.

With Aratum’s WMS solutions, you can achieve maximum profitability and reach new heights in your industry.

Cloud/Multi-Cloud/Hybrid Solutions

IoT Integration

Security with Identity Access Management (IAM)

Automation with Shipping Rules

Advanced Shipping Notifications

Real-time shelf & storage visibility: First In, First Out (FIFO) Inventory Management

Out-of-the-box billing and invoicing

One-click generation of pick-and-pack lists

Customization of labels

Aratum’s WMS provides different deployment options, including cloud, multi-cloud, and hybrid solutions. These options are designed to meet the specific needs of various businesses. You can choose the deployment model that best fits your IT infrastructure, whether you prefer the flexibility and accessibility of cloud-based systems or the control of on-premises solutions.

Integrating with Internet of Things (IoT) devices enhances operational efficiency by tracking inventory, equipment, and environmental conditions. It facilitates the collection of substantial data quantities for actionable insights to optimize warehouse performance and predict maintenance needs.

Security is a top priority for Aratum’s WMS, which incorporates Identity Access Management (IAM) to provide robust access controls and protect sensitive warehouse data.

The IAM system guarantees that only authorized personnel can access critical warehouse functions through secure user authentication, single sign-on, and multi-factor authentication.

Aratum’s WMS automates the shipping process using predefined rules, such as carrier selection and shipping methods, to optimize workflows and lessen manual inputs.

Ensure that your employees excel in clearly defined tasks by scheduling processes with efficient task allocation to maintain quality in distribution. Aratum’s user-friendly interface makes it easy to train staff quickly, eliminating the frustration of a steep learning curve and keeping operations smooth.

The advanced shipping notification feature in Aratum’s WMS improves customer communication by providing real-time updates on order status, shipment tracking, and delivery schedules. This approach enhances the customer experience by keeping them informed throughout shipping, driving trust and transparency.

Aratum's WMS supports FIFO inventory management, allowing businesses to prioritize older stock for order fulfillment. This ensures that perishable items or those with expiration dates are used or shipped in the correct order, reducing waste and maintaining product freshness. By implementing FIFO, companies can improve stock accuracy, enhance compliance with industry regulations, and optimize inventory turnover.

With built-in billing and invoicing capabilities, Aratum’s WMS simplifies financial operations by automating the generation of accurate invoices to lessen administrative burdens and streamline accounting processes. The system integrates seamlessly with existing accounting software, enabling up-to-date records for fast reconciliations and improved cash flow management.

Aratum’s WMS features a one-click generation of pick-and-pack lists, significantly speeding up the order fulfillment process by simplifying the preparation of orders. This automation reduces the time needed for staff to compile and execute picking tasks, minimizing errors and improving order accuracy.

Customizing labels in Aratum’s WMS allows businesses to create labels tailored to specific requirements, such as branding, regulatory compliance, or unique product identifiers. This feature enhances operational flexibility, allowing companies to adapt quickly to different customer needs, shipping standards, and industry regulations.

Aratum WMS software ensures the accurate and timely distribution of medical supplies, optimizes inventory levels and maintains compliance with regulations to support efficient healthcare facility operations.

Aratum WMS software ensures the proper handling and tracking of temperature-sensitive medications, regulatory compliance, and efficient distribution to support patient care and safety.

Aratum WMS software optimizes material flow, inventory accuracy, and production processes, ensuring the timely availability of raw materials and finished goods to meet production schedules and customer demands.

Aratum WMS software streamlines inventory control, order processing, and distribution logistics, enhancing store replenishment, optimizing stock levels, and ensuring seamless product availability across brick-and-mortar locations and online channels to meet diverse customer demands and drive sales growth.

Aratum WMS software orchestrates the efficient storage, retrieval, and dispatch of products, optimizing inventory accuracy, order fulfillment speed, and overall operational efficiency to meet the demands of online shoppers and maintain a competitive advantage in the digital marketplace.

Aratum WMS software monitors and controls temperature-sensitive storage environments, ensuring the integrity of perishable goods throughout the supply chain, from production to delivery.

Aratum WMS software streamlines the storage and distribution of parts and assemblies, ensuring just-in-time delivery and efficient inventory control to support continuous manufacturing processes.

Aratum WMS software streamlines the flow of goods, optimizes storage space utilization, and enhances order fulfillment processes, improving efficiency and customer satisfaction.

Aratum WMS software enhances the organization and flow of raw materials, components, and finished products, optimizing inventory accuracy and production efficiency to meet stringent manufacturing schedules.

Aratum WMS software enforces strict safety protocols, regulatory compliance, and specialized handling procedures to mitigate hazardous material storage and transportation risks.

Due to the unforeseen demand for its products, a growing herbal supplement company in the USA needed more efficiency in its warehouse operations. The company relied on manual inventory, leading to several stockouts, delayed order fulfillment, and compliance issues.

Faced with these problems, they turned to our solutions to improve their warehouse operations.

Warehouse management systems involve the planning, organizing, and controlling of warehouse operations to ensure the efficient storage, handling, and movement of goods within a supply chain.

A warehouse management system is crucial for optimizing inventory control, order fulfillment, and overall supply chain efficiency. This can lead to cost savings, improved customer satisfaction, and competitive advantage.

Key factors to consider include the business’s specific needs, scalability, ease of integration with existing systems, customization options, cost, user-friendliness, and the vendor’s level of support and training.

Yes, using Aratum’s WMS software can be tailored to the needs of small businesses. Scalable solutions are available that can grow as the company expands, and even small warehouses benefit from improved inventory management, faster order fulfillment, and better space utilization.

Aratum’s WMS software helps pharmaceutical, food, and other industries comply with regulatory requirements by enforcing temperature controls, lot tracking, expiration date management, and documentation management.

Aratum’s WMS software integrates with other systems, such as ERP (Enterprise Resource Planning), TMS (Transportation Management System), and CRM (Customer Relationship Management), to ensure seamless data flow and coordination across the supply chain.

Aratum’s WMS software offers reporting and analytics tools that measure key performance indicators (KPIs) such as order accuracy, pick and pack times, labor productivity, stock turnover, and on-time shipments. These metrics help warehouse managers identify areas for improvement and make data-driven decisions.

The implementation time for a WMS varies depending on the size of the warehouse, the complexity of the operations, and the level of customization required. A typical implementation can take anywhere from a few weeks to several months.

To implement enterprise performance management software, you can rely on Aratum solutions tailored to your business requirements. These solutions can help you get started and gain visibility, efficiency, and resiliency.

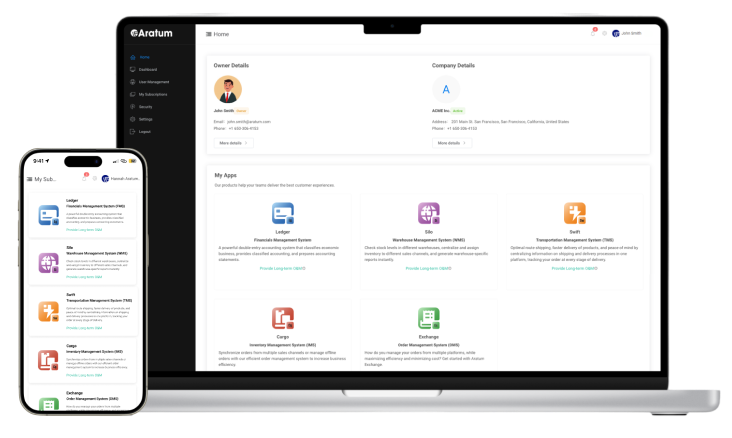

Aratum is a globally recognized software provider specializing in developing supply chain management solutions. Our software solutions incorporate advanced algorithms and optimized data structures to facilitate efficient data processing and information dissemination across organizations.

Leveraging cutting-edge technologies such as machine learning and artificial intelligence, the software enables automated decision-making and real-time analytics, enhancing supply chain visibility and improving overall performance.

With a focus on delivering robust and scalable solutions, Aratum is committed to providing our clients with the tools necessary to optimize their supply chain operations and gain a competitive edge in your respective markets.

© 2024 Aratum or an Aratum affiliate company. All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of Aratum or an Aratum affiliate company. The information contained herein may be changed without prior notice. Some software products marketed by Aratum and its distributors contain proprietary software components of other software vendors. National product specifications may vary. These materials are provided by Aratum or an Aratum affiliate company for informational purposes only, without representation or warranty of any kind, and Aratum or its affiliated companies shall not be liable for errors or omissions with respect to the materials. The only warranties for Aratum or Aratum affiliate company products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. In particular, Aratum or its affiliated companies have no obligation to pursue any course of business outlined in this document or any related presentation, or to develop or release any functionality mentioned therein. This document, or any related presentation, and Aratum’s or its affiliated companies’ strategy and possible future developments, products, and/or platforms, directions, and functionality are all subject to change and may be changed by Aratum or its affiliated companies at any time for any reason without notice. The information in this document is not a commitment, promise, or legal obligation to deliver any material, code, or functionality. All forward-looking statements are subject to various risks and uncertainties that could cause actual results to differ materially from expectations. Readers are cautioned not to place undue reliance on these forward-looking statements, and they should not be relied upon in making purchasing decisions. Aratum and other Aratum products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Aratum (or an Aratum affiliate company) globally. All other product and service names mentioned are the trademarks of their respective companies. See aratum.com for additional trademark information and notices.