In today’s fast-paced and complex logistics landscape, yard management system (YMS) has become an indispensable tool for optimizing efficiency and maintaining a competitive edge over the market. With Aratum Solutions, you meet the demands of your modern supply chain with agility and precision. Explore the potential of YMS in driving sustainable growth for your business.

Real-Time Tracking

Automated Check-In and Check-Out

Dock and Gate Management

Inventory Management

Yard Slotting

Environmental Monitoring

Security Management

Maintenance Management

Real-time tracking allows continuous monitoring of all vehicles and equipment within the yard. This feature ensures that all movements are logged and visible, facilitating efficient management and quick responses to any issues or delays.

Automated check-in and check-out streamline the entry and exit processes for vehicles. They reduce manual paperwork and errors, speed up operations, and enhance security by ensuring only authorized vehicles access the yard.

This feature optimizes the assignment and usage of docks and gates. It helps prevent bottlenecks, ensures efficient loading and unloading operations, and maximizes the utilization of available space.

Inventory management within a YMS tracks the location and status of all trailers and containers. It allows accurate inventory counts, reduces misplaced items, and ensures timely retrieval of needed assets.

Yard slotting optimizes the allocation of parking spaces for trailers and containers. This feature ensures that the yard layout is utilized effectively, reducing the time and effort needed to locate and move assets.

Environmental monitoring within a YMS tracks conditions crucial for perishable goods, such as temperature and humidity. It ensures compliance with regulatory requirements and protects the quality of sensitive cargo.

Security management features monitor and control access to the yard, ensuring that only authorized personnel and vehicles enter. It enhances the safety of assets and personnel by preventing unauthorized access and potential theft.

Maintenance management schedules and tracks the upkeep of yard equipment and vehicles. Regular maintenance ensures the reliability and safety of operations, reducing downtime and costly repairs.

YMS manages the flow of goods in and out of retail facilities, optimizes yard space, and coordinates with transportation providers.

YMS manages inbound and outbound logistics, tracks inventory of raw materials and finished goods, and optimizes yard space for storage and staging.

Freight terminals, trucking companies, and third-party logistics providers use YMS to manage trailer movements, optimize dock utilization, and improve truck turnaround times.

YMS optimizes inbound and outbound logistics, manages temperature-sensitive products, maximizes yard space utilization, ensures regulatory compliance, integrates with supply chain partners, and enhances overall operational efficiency.

Automotive manufacturing plants and distribution centers use YMS to manage vehicle and part movement, optimize storage and staging areas, and coordinate inbound and outbound logistics.

Facilities handling perishable goods, such as grocery distribution centers and cold chain logistics providers, use YMS to ensure efficient handling of temperature-sensitive products and compliance with storage regulations.

Sorting centers and distribution hubs in the parcel delivery industry use YMS to manage the flow of packages, optimize dock operations, and coordinate with delivery vehicles for efficient loading and unloading.

YMS helps construction companies and building materials suppliers manage the movement of construction materials, optimize yard space, and coordinate deliveries to construction sites.

E-commerce fulfillment centers benefit from YMS in managing high-volume inbound and outbound shipments, optimizing dock operations, and coordinating with carriers for timely deliveries.

Airports and air cargo handling facilities use YMS to manage the movement and storage of containers and pallets, optimize gate and apron utilization, and coordinate with ground handling services.

A large logistics company had several challenges regarding their yard management. Employees frequently complained about congested yard areas, where finding specific containers became time-consuming and labor-intensive. High turnaround times during check-in, check-out, and dock scheduling processes frequently caused delays in loading and unloading operations.

These problems did not only frustrate the company’s personnel, but also their partners and clients.

The company sought our yard management system to optimize its operations in response to these challenges.

A Yard Management System (YMS) is a software solution designed to manage the movement and storage of trailers and containers within a yard or distribution center. It provides real-time visibility, automates processes, and enhances efficiency in yard operations.

Implementing a YMS improves operational efficiency by optimizing yard space utilization, reducing trailer handling times, minimizing congestion, improving labor productivity, and enhancing overall supply chain visibility and responsiveness.

A YMS improves operational efficiency by automating check-in/check-out processes, dock scheduling, inventory management, and yard space allocation. Real-time tracking and data analytics also help make informed decisions that optimize yard operations.

Facilities such as distribution centers, warehouses, manufacturing plants, retail distribution hubs, and transportation terminals benefit from using a YMS to streamline yard operations, improve throughput, and enhance overall logistics management.

YMS integrates with other enterprise systems, such as Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and Enterprise Resource Planning (ERP) systems. This integration ensures seamless data flow across all logistics and supply chain operations.

Yes, a good YMS can be customized to fit specific operational needs and business requirements. Customization options may include tailored workflows, reporting formats, user interfaces, and integration with existing systems.

Challenges may include initial setup and configuration, integration with existing systems, data accuracy and consistency, user adoption, and ensuring compatibility with operational workflows. However, these challenges can be addressed with proper planning and support.

The ROI of a YMS includes reduced labor costs, improved yard utilization, increased throughput, better asset visibility, enhanced customer service levels, and compliance with regulatory requirements. It varies depending on the specific needs and scale of operations.

YMS supports sustainability initiatives by optimizing yard operations, reducing vehicle idle time, minimizing fuel consumption, and lowering carbon emissions. It contributes to efficient resource utilization and environmental stewardship.

A Yard Management System focuses on managing the movement and storage of trailers and containers within a yard or distribution center. In contrast, a Warehouse Management System primarily manages inventory within a warehouse, including receiving, storage, picking, and shipping.

A YMS is scalable and can grow with your business needs. It can accommodate increases in yard size, throughput volume, and operations complexity by adding additional features or modules or integrating with other systems as required.

To implement an effective yard management system in your industry, you can rely on Aratum software solutions tailored to your business requirements to help you get started and gain visibility, efficiency, and resiliency.

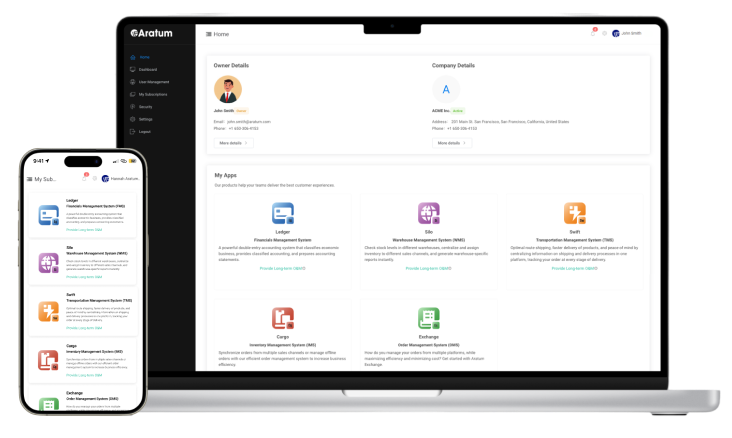

Aratum is a globally recognized software provider specializing in developing supply chain management solutions. Our software solutions incorporate advanced algorithms and optimized data structures to facilitate efficient data processing and information dissemination across organizations.

Leveraging cutting-edge technologies such as machine learning and artificial intelligence, the software enables automated decision-making and real-time analytics, enhancing supply chain visibility and improving overall performance.

With a focus on delivering robust and scalable solutions, Aratum is committed to providing our clients with the tools necessary to optimize their supply chain operations and gain a competitive edge in your respective markets.

© 2024 Aratum or an Aratum affiliate company. All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of Aratum or an Aratum affiliate company. The information contained herein may be changed without prior notice. Some software products marketed by Aratum and its distributors contain proprietary software components of other software vendors. National product specifications may vary. These materials are provided by Aratum or an Aratum affiliate company for informational purposes only, without representation or warranty of any kind, and Aratum or its affiliated companies shall not be liable for errors or omissions with respect to the materials. The only warranties for Aratum or Aratum affiliate company products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. In particular, Aratum or its affiliated companies have no obligation to pursue any course of business outlined in this document or any related presentation, or to develop or release any functionality mentioned therein. This document, or any related presentation, and Aratum’s or its affiliated companies’ strategy and possible future developments, products, and/or platforms, directions, and functionality are all subject to change and may be changed by Aratum or its affiliated companies at any time for any reason without notice. The information in this document is not a commitment, promise, or legal obligation to deliver any material, code, or functionality. All forward-looking statements are subject to various risks and uncertainties that could cause actual results to differ materially from expectations. Readers are cautioned not to place undue reliance on these forward-looking statements, and they should not be relied upon in making purchasing decisions. Aratum and other Aratum products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Aratum (or an Aratum affiliate company) globally. All other product and service names mentioned are the trademarks of their respective companies. See aratum.com for additional trademark information and notices.