Disconnected data systems, inefficient collaboration among cross-functional teams, and strict regulatory requirements can lead to challenges and increased costs in product lifecycle management. Aratum’s robust PLM software centralizes product data, streamlines processes, and enhances collaboration, ensuring all stakeholders access accurate, up-to-date information.

Centralized Data Management

Collaboration Tools

Document and Change Management

Product Design and Development

Bill of Materials (BOM) Management

Regulatory Compliance

Supplier and Materials Management

Manufacturing Process Management

Quality Management

Lifecycle Analytics and Reporting

Sustainability and End-of-Life Management

Customer Feedback Integration

PLM systems provide a single source of truth for all product-related information, ensuring everyone in the organization has access to the latest data. This

Leverage a mix of public cloud, private cloud, and on-premises infrastructure to meet diverse business requirements, accommodating varying workloads and data sensitivity levels.

PLM systems facilitate the management of documents and changes, ensuring that revisions are tracked, approved, and implemented efficiently. This helps maintain consistency, reduces errors, and ensures compliance with industry standards.

These systems support the design and development phase with features like CAD integration, simulation, and analysis. This helps improve design quality, reduce prototyping costs, and accelerate time to market.

Enable supply chain businesses to implement comprehensive disaster recovery strategies by replicating data and applications across geographically dispersed environments, ensuring rapid recovery during outages or disasters.

PLM systems help ensure products comply with industry regulations and standards by maintaining documentation and facilitating compliance checks. This reduces the risk of non-compliance and potential legal issues.

PLM systems assist in managing relationships with suppliers and tracking material specifications. This ensures the quality and availability of components throughout the product lifecycle, supporting reliable production schedules.

These systems streamline manufacturing processes by integrating design and manufacturing data. Improved production efficiency and reduced time to market are achieved through better coordination and data accuracy.

PLM systems include quality assurance features, helping identify and rectify issues early in the product lifecycle. This proactive approach improves product reliability and enhances customer satisfaction.

PLM provides robust analytics and reporting tools that offer insights into product performance, costs, and market trends. These insights support strategic decision-making and continuous improvement efforts.

PLM systems help manage a product's end-of-life phase, including disposal, recycling, and compliance with environmental regulations. This promotes sustainability and reduces the product's environmental impact.

These systems enable the collection and integration of customer feedback into the product development process. This ensures that products meet market needs and customer expectations, driving higher satisfaction and loyalty.

PLM streamlines the development, regulatory compliance, and production processes of medical devices and drugs, ensuring high quality and faster time-to-market.

PLM enhances product development, inventory management, and merchandising strategies, enabling faster time-to-market, improved product quality, and better alignment with consumer trends.

PLM streamlines product information management enhances inventory control, and improves supply chain coordination, leading to greater efficiency and better service to retailers.

PLM optimizes product data management, enhances inventory control, and accelerates the introduction of new products to market, thereby improving operational efficiency and customer satisfaction.

PLM efficiently manages and tracks orders, optimizes route planning, and enhances fleet management, leading to improved delivery performance and reduced operational costs.

PLM ensures the integrity and quality of temperature-sensitive products by optimizing logistics, monitoring storage conditions, and enhancing regulatory compliance throughout the supply chain.

PLM ensures strict adherence to safety regulations, meticulously monitors storage conditions, and facilitates efficient handling and disposal processes. It mitigates risks and ensures compliance throughout the product lifecycle.

PLM enhances product innovation, streamlines supply chain processes, and ensures compliance with regulations, leading to faster product launches and improved market responsiveness.

PLM optimizes inventory control, monitors shelf life, and coordinates efficient distribution, ensuring freshness and minimizing waste throughout the supply chain.

PLM oversees product development and streamlines production processes. It ensures quality control throughout the manufacturing lifecycle, enhancing efficiency, reducing time to market, and maintaining product consistency.

A leading supermarket in the south of Sweden had trouble with product data being spread across disconnected systems. The lack of a centralized system for tracking product information and regulatory requirements made ensuring compliance with local regulations and maintaining high-quality standards challenging.

The company sought our product lifecycle management software to optimize its operations.

Product Lifecycle Management (PLM) is a strategic approach and comprehensive software solution for managing a product’s entire lifecycle, from its inception through engineering design and manufacture to service and disposal. PLM integrates people, processes, business systems, and information to ensure all stakeholders can access accurate, up-to-date product data throughout its lifecycle. This helps organizations streamline operations, reduce time to market, improve product quality, and enhance collaboration across departments and external partners.

Product Lifecycle Management software is a system that helps manage a product’s entire lifecycle, from ideation and design through manufacturing, distribution, and eventual disposal.

PLM software provides a centralized platform on which cross-functional teams can collaborate in real-time on design, engineering, procurement, and manufacturing processes, ensuring everyone works with the latest information.

PLM software helps manage regulatory requirements by maintaining compliance documentation, tracking changes, and ensuring that products meet industry standards throughout their lifecycle.

Yes, PLM software can integrate with ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), CAD (Computer-Aided Design), and other systems to streamline data exchange and improve overall business processes.

PLM software aids NPD by facilitating collaboration among design teams, managing prototypes, conducting simulations and analysis, and optimizing the design-to-manufacturing process.

PLM software enhances supply chain management by improving visibility into product data, optimizing inventory levels, ensuring timely delivery, and effectively managing supplier relationships.

PLM software facilitates quality management by tracking defects, conducting quality audits, enforcing standardized processes, and ensuring continuous improvement throughout the product lifecycle.

Challenges may include data migration issues, user resistance to change, integration complexities with existing systems, and ensuring user adoption across departments.

PLM software reduces costs by minimizing design iterations, optimizing resource allocation, improving supply chain efficiency, and reducing time spent on manual processes and errors.

Yes, PLM software solutions are available for businesses of all sizes, with options ranging from basic functionalities for small enterprises to comprehensive suites for large global corporations.

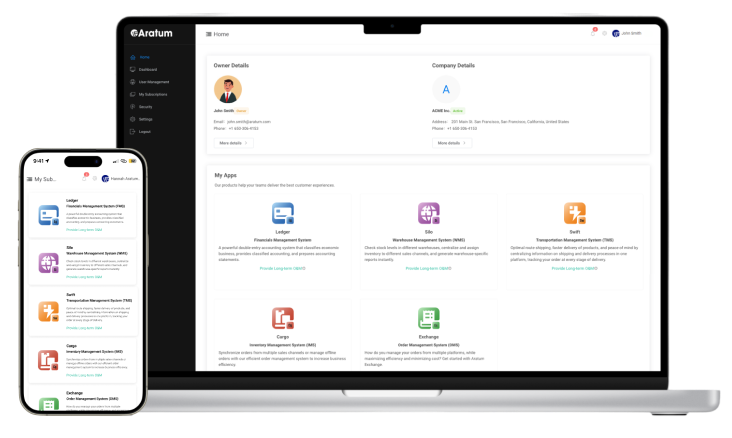

To implement effective product lifecycle management in your industry, you can rely on Aratum software solutions tailored to your business requirements to help you get started and gain visibility, efficiency, and resiliency.

Aratum is a globally recognized software provider specializing in developing supply chain management solutions. Our software solutions incorporate advanced algorithms and optimized data structures to facilitate efficient data processing and information dissemination across organizations.

Leveraging cutting-edge technologies such as machine learning and artificial intelligence, the software enables automated decision-making and real-time analytics, enhancing supply chain visibility and improving overall performance.

With a focus on delivering robust and scalable solutions, Aratum is committed to providing our clients with the tools necessary to optimize their supply chain operations and gain a competitive edge in your respective markets.

© 2024 Aratum or an Aratum affiliate company. All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of Aratum or an Aratum affiliate company. The information contained herein may be changed without prior notice. Some software products marketed by Aratum and its distributors contain proprietary software components of other software vendors. National product specifications may vary. These materials are provided by Aratum or an Aratum affiliate company for informational purposes only, without representation or warranty of any kind, and Aratum or its affiliated companies shall not be liable for errors or omissions with respect to the materials. The only warranties for Aratum or Aratum affiliate company products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. In particular, Aratum or its affiliated companies have no obligation to pursue any course of business outlined in this document or any related presentation, or to develop or release any functionality mentioned therein. This document, or any related presentation, and Aratum’s or its affiliated companies’ strategy and possible future developments, products, and/or platforms, directions, and functionality are all subject to change and may be changed by Aratum or its affiliated companies at any time for any reason without notice. The information in this document is not a commitment, promise, or legal obligation to deliver any material, code, or functionality. All forward-looking statements are subject to various risks and uncertainties that could cause actual results to differ materially from expectations. Readers are cautioned not to place undue reliance on these forward-looking statements, and they should not be relied upon in making purchasing decisions. Aratum and other Aratum products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Aratum (or an Aratum affiliate company) globally. All other product and service names mentioned are the trademarks of their respective companies. See aratum.com for additional trademark information and notices.